When sourcing raw materials for manufacturing or distribution, carbon steel vs cast iron are two of the most widely used alloys in global industries. Both are iron-carbon alloys, but their differences in composition, mechanical properties, and production methods make them suitable for different industrial applications.

Whether you’re a manufacturer, distributor, or project contractor, understanding these differences between carbon steel and cast iron will help you select the right material, control costs, and ensure long-term performance.

What is Cast Iron?

Cast iron is an iron-carbon alloy containing 2–4% carbon and silicon, manganese, and trace elements. It is produced by melting iron and pouring it into molds, creating components with a dense, rigid structure.

Industrial characteristics:

High compressive strength – suitable for heavy-load applications.

Excellent vibration damping – ideal for machinery bases and automotive parts.

High wear resistance – long service life in abrasive environments.

Applications – engine blocks, machine tool frames, pump housings, pipes, and manhole covers.

What is Carbon Steel?

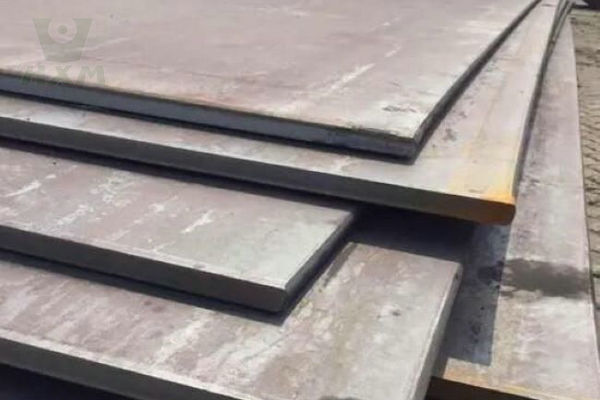

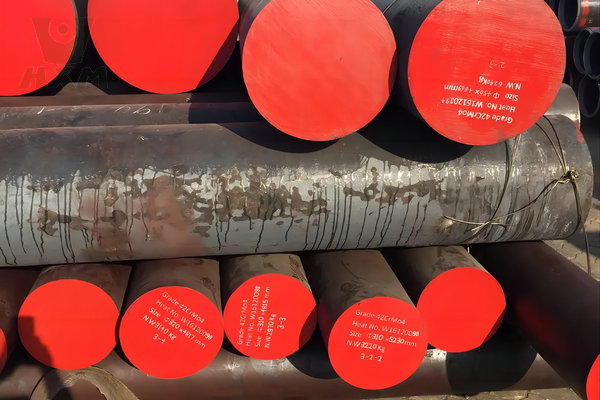

Carbon steel is an iron-carbon alloy with a lower carbon content (typically 0.05%–2.0%), available in various grades such as low, medium, and high carbon steel. It is manufactured by rolling or forging, which allows for more versatile shapes and thicknesses.

Industrial characteristics:

High tensile strength – ideal for load-bearing structures.

Good ductility – easier to shape, weld, and machine.

Wide size availability – from thin sheets to heavy plates and structural beams.

Applications – construction beams, automotive frames, pressure vessels, pipelines, and machinery parts.

Difference Between Cast Iron vs Carbon Steel

Although both materials are iron-carbon alloys, their production methods and carbon content lead to significant differences in properties and uses.

1. Construction Design

Cast Iron: Molded into shape; excellent for complex castings with high rigidity.

Carbon Steel: Rolled or forged; available in sheets, bars, and structural sections for fabrication.

2. Heat Distribution

Cast Iron: Withstands high temperatures and retains heat well, suitable for industrial furnaces or high-heat components.

Carbon Steel: Heats and cools quickly, better for applications requiring thermal responsiveness.

3. Safety Durability

Cast Iron: Excellent resistance to wear and deformation; brittle under impact.

Carbon Steel: Strong under impact loads; better suited for high-tensile applications.

4. Ease of Use

Cast Iron: Requires casting molds; machining is more challenging.

Carbon Steel: Easier to cut, weld, and machine for custom fabrication.

5. Nonstick Coating (Not applicable in industrial context)

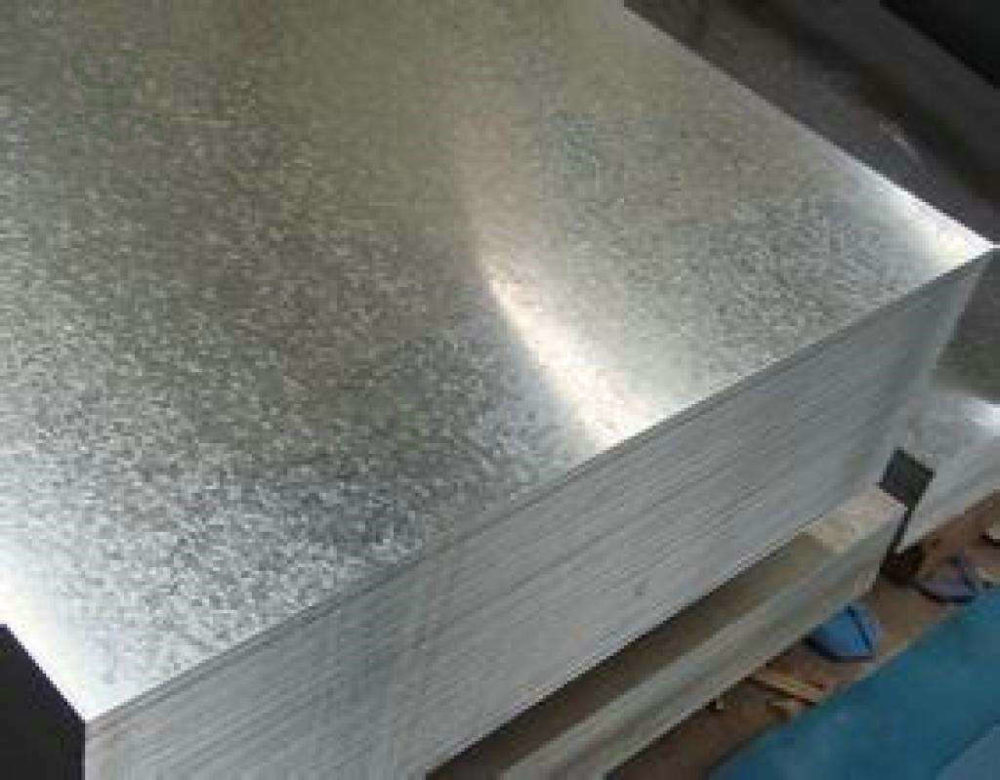

In industrial terms, this relates to surface treatments such as galvanizing, painting, or powder coating for corrosion protection.

6. Maintenance

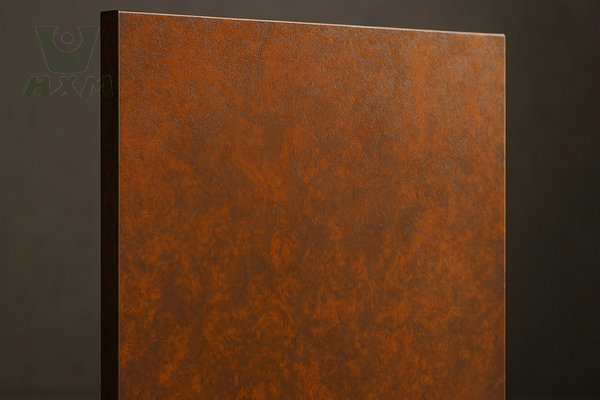

Cast Iron: Requires protection from rust; often coated or painted.

Carbon Steel: Also prone to rust without treatment, but easier to maintain through surface coatings.

7. Cost Considerations

Cast Iron: Generally lower raw material cost; economical for high-volume castings.

Carbon Steel: May cost more per ton depending on grade and processing, but offers higher versatility.

8. Energy Consumption

Cast Iron: High thermal mass can improve energy efficiency in certain machinery.

Carbon Steel: Lighter and often more efficient for transport and assembly.

Carbon Steel vs Cast Iron: Additional Technical Considerations

Corrosion Resistance – Both materials can corrode, but carbon steel can be more effectively treated with galvanizing or special coatings. Cast iron’s natural structure offers some wear resistance but is still prone to rust without protection.

Density & Weight – Similar densities (~7.8 g/cm³), but component design affects total weight. Weight is critical for shipping and structural load calculations.

Fatigue Resistance – Carbon steel generally has better performance under repeated stress, making it ideal for moving or load-cycling parts.

Temperature Performance – Cast iron is stable under high heat, while carbon steel performs better in low-temperature, impact-prone environments.

Recyclability – Both materials are recyclable; buyers with environmental certifications may require proof of recycled content.

Carbon Steel vs Cast Iron: Commercial Factors for Buyers

Market Price Volatility – Cast iron prices tend to be more stable, while carbon steel prices can fluctuate with steel scrap and energy costs.

Lead Time & Supply Chain – Cast iron production requires mold preparation, leading to longer lead times. Carbon steel products can be fabricated faster from stock material.

Customization Capability – Carbon steel is highly flexible for fabrication, while cast iron is more cost-effective for high-volume, uniform designs.

Lifecycle Cost – Consider total cost over the material’s lifespan, including maintenance, downtime, and replacement frequency.

Compliance & Certification – Many industries require materials to meet ASTM, EN, JIS, or ISO standards. Buyers should ensure the supplier can provide mill test reports and certification documents.

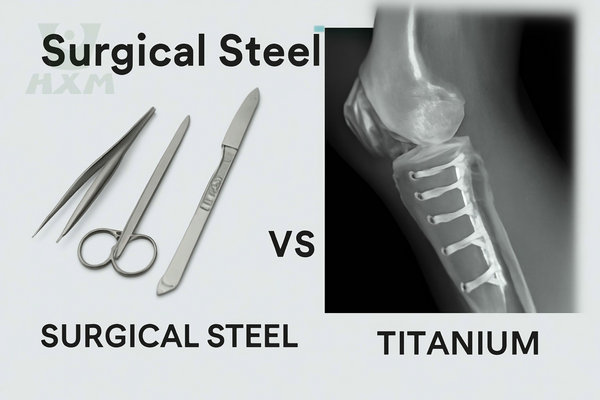

Advantages of Surgical Steel

Corrosion Resistance

Surgical steel is highly resistant to corrosion due to its high chromium content, making it ideal for medical applications that come in contact with moisture or bodily fluids.

Strength and Durability

The hardness of surgical steel allows it to withstand high levels of stress and pressure, making it perfect for surgical instruments and tools that require long-lasting durability.

Versatility

Surgical steel can be easily formed into various shapes, making it highly versatile for different medical tools and implants.

Carbon Steel vs Cast Iron Comparison Chart

Property | Carbon Steel | Cast Iron |

|---|---|---|

Core Process | Plastic forming, cutting, welding | Melting, casting |

Main Advantages | High strength, high toughness, easy welding, easy machining | High compressive strength, strong damping capacity, can form complex shapes |

Main Disadvantages | Shape flexibility limited by machining | Brittle, low tensile strength, difficult to weld |

Machinability | Excellent | Fair to poor (depends on type) |

Weldability | Excellent | Poor to moderate (requires special processes) |

Typical Applications | Structural steel, pipes, car bodies, pressure vessels | Engine blocks, machine tool bases, valves, water pipes, gearboxes |

Cost Structure | Higher raw material cost, but flexible processing | Lower raw material cost, but high mold costs |

Pros and Cons of Carbon Steel vs Cast Iron

Cast Iron Pros

High wear resistance

Excellent vibration damping

Cost-effective for casting

Long service life in static load applications

Cast Iron Cons

Brittle under impact loads

Heavier weight

Lower ductility

Carbon Steel Pros

High tensile strength

Good weldability and machinability

Suitable for dynamic load applications

Available in multiple grades and forms

Carbon Steel Cons

Higher cost for certain grades

Requires protective coatings for corrosion resistance

Carbon Steel vs Cast Iron: Which is Better?

Choose cast iron if:

You need complex shapes with high compressive strength.

Your application requires excellent wear resistance and vibration damping.

Choose carbon steel if:

You need high tensile strength and impact resistance.

You require material that is easy to weld, cut, and machine.

Your project involves dynamic or structural loads.

For many industrial buyers, the decision depends on application requirements, budget, and lead time. Consulting with your supplier can ensure the best material choice for your specific project.

FAQ

Can we provide specific grades of these two materials?

Yes. We can offer a variety of carbon steel and cast iron grades according to international standards (such as ASTM, SAE, DIN, and GB) to meet your exact specifications.

Which is stronger, carbon steel or cast iron?

Carbon steel has higher tensile strength and impact resistance, while cast iron has higher compressive strength.

Can carbon steel and cast iron be used together?

Yes, many machines use carbon steel for structural parts and cast iron for wear components.

What is the price difference per ton?

Cast iron is usually cheaper per ton, but processing and finishing can affect final costs.

How do I prevent rust on these materials?

Use protective coatings, paints, or galvanizing to extend service life.

Do you supply both carbon steel and cast iron in bulk?

Yes, we provide bulk supply for manufacturing, construction, and distribution.

Looking for a reliable carbon steel or cast iron supplier for your next project?

Contact us today for material specifications, bulk pricing, and global shipping options.