Welcome to Coated Steel Products

Huaxiao Metal has more than 10 years of metal manufacturing experience and is one of the leading coated steel manufacturers in China. Coated Steel Products Co., Ltd. is headquartered in Shanghai, China, and can provide coated steel products from all over the world.

We can provide you with a complete envelope solution including roof and wall options. Manufactured using only the highest standards of quality finishes and materials, the range offers design freedom and a warranty of up to 40 years.

Our renowned roof and wall cladding profiles are complemented by a wide range of building profiles including column shells, cappings, louvers, soakers, rainwater systems, pressed and curved steel flashings, and more.

Coated Steel Products

Coated steel products are steel materials that have been treated or coated with various substances to enhance their performance, durability, and resistance to corrosion or other environmental factors. The coating is typically applied to the surface of the steel to provide protection, improve aesthetics, or add specific functional properties. Here are some common types of coated steel products:

Galvalume Steel

Galvalume Steel Suppliers and Manufacturers Huaxiao Metal supplies galvalume steel, which combines the durable properties of aluminum, silicon, and zinc to provide excellent rust resistance.

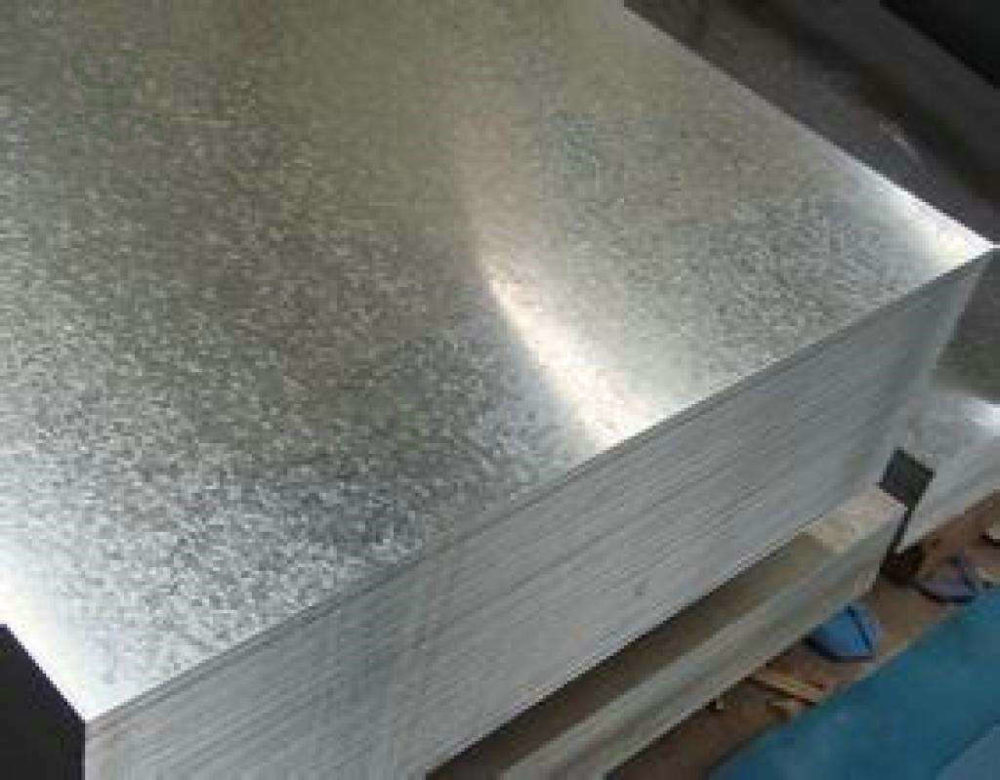

Galvanized Sheet Metal

Galvanized Sheet Metal Factory and Manufacturer Galvanized sheet is one of the most commonly used sheet types in manufacturing. Many steelmakers and fabricators will tell

Tin Plate

Tin Plate Factory and Manufacturer – Huaxiao Metal For decades, Huaxiao Metal has been supplying high-quality tinplate and tin coated steel in a variety of

Aluminized Steel

Aluminized Steel Supplier | Aluminized Steel Manufacturer – Huaxiao Metal Aluminized Steel is a type of steel with high corrosion and heat resistance. It is

Color Stone Metal Tile

Metal Colored Stone/Rainbow Roof Tiles Manufacturers Our premium metal colored stone and rainbow roof tiles combine modern design with exceptional durability to add a unique

EGI

Electro Galvanized Steel (EGI) Suppliers Electro-galvanized steel, often abbreviated as EG or EGI, is a type of steel that has undergone a special electroplating process

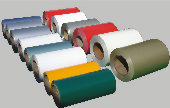

PPGI/PPGL/PPGF

PPGI/PPGL/PPGF Steel Suppliers Are you looking for PPGI/PPGL/PPGF Steel Suppliers? Our company provides high-quality and competitively priced PPGI (pre-painted galvanized steel), PPGL (pre-painted galvanized steel),

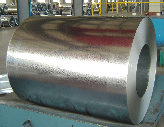

GL/GF

Hot-Dip Galvanfan / Galvalume Steel Suppliers Hot dip galvanizing and galvalume are two different processes used to protect steel from corrosion. They involve applying a

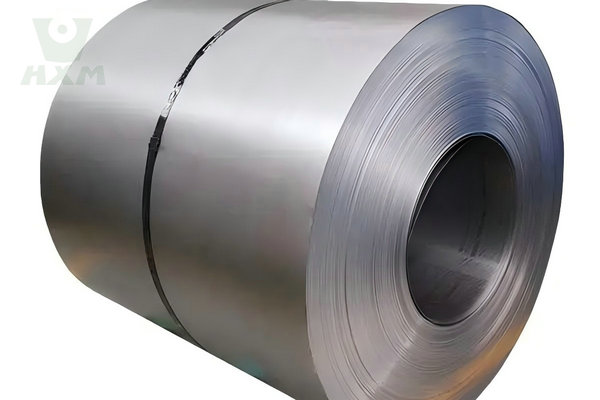

GI

GI Galvanized Steel Coils Suppliers Huaxiao Metal is a leading supplier of galvanized steel sheets and coils. Galvanized steel is defined as carbon steel plated

Applications for Coated Steel Products

Coated steel products find a wide range of applications across various industries due to their enhanced properties, such as corrosion resistance, durability, and aesthetic appeal. Here are some common applications for coated steel products:

- Construction and Architecture

- Automotive Industry

- Transportation

- Appliances

- Packaging

- Food and Beverage Cans

- Aerosol Cans

- Electrical Enclosures

- Agriculture

- Oil and Gas Industry

- Pipelines

- Bridges

- Highway Guardrails

- Marine Industry

The specific type of coating and steel product chosen depends on the application’s requirements, including environmental conditions, load-bearing capabilities, and desired longevity. Coated steel products continue to be a versatile and crucial material in many industries, contributing to the longevity and functionality of various products and structures.

Benefits of Coated Steel

Coated steel’s main features include:

- Corrosion Resistance: Protection against rust and corrosion, extending the lifespan of the steel.

- Durability: Increased resistance to scratches, abrasion, and wear, suitable for harsh environments.

- Aesthetic Options: Various colors and finishes are available, enhancing visual appeal for different applications.

- Weather Resistance: Ability to withstand exposure to sunlight, rain, snow, and humidity, ideal for outdoor use.

- Chemical Resistance: Protection against corrosive substances, making it suitable for chemical environments.

- Formability: Improved ability to be shaped, bent, or stamped without damaging the protective coating

Overall, coated steel improves the life, performance, and appearance of steel products in applications. If you are purchasing coated steel, you may wish to contact us to provide you with competitive coated steel prices!

The Difference of Coated Steel and Power Coated Steel

Coated steel and powder-coated steel differ in their application methods and characteristics:

Coated Steel:

- Coated steel refers to steel that has been coated to enhance its properties such as corrosion resistance, durability, and aesthetics.

- Coatings can be applied by a variety of methods, including hot-dip galvanizing, electro-galvanizing, and organic coatings such as painting.

- Coatings can be made from zinc, aluminum, or organic materials, depending on the desired properties and application requirements.

- Coated steel is widely used in construction, automobiles, home appliances, and other industrial fields.

Powder-Coated Steel:

- Powder-coated steel refers specifically to steel that is coated with dry powder by electrostatic spraying and solidified under heating conditions to form a hard surface.

- The powder coating process involves spraying charged powder particles onto a steel surface, where they adhere due to electrostatic attraction. Then, with heat, the powder melts and forms a durable, smooth coating.

- Powder coatings are typically made from polyester, epoxy, or a combination of the two and offer excellent corrosion resistance, durability, and aesthetics.

- Powder-coated steel is widely used in the construction, furniture, automotive, and consumer goods industries due to its excellent coating quality, resistance to peeling, and scratching, colorfastness, and environmental friendliness (low VOC emissions).

In summary, both coated and powder-coated steel enhance performance, but their main differences lie in the application method and characteristics of the coating. Coated steel covers a wider range of coating methods and materials, while powder-coated steel refers specifically to steel that has been electrostatically applied with a dry powder and cured.

If you need to know more, you can contact us directly!

Coated Steel Production and Processing

Coated steel production and processing is a process that covers the surface of steel plates with different types of coatings to improve the corrosion resistance, aesthetics, and other properties of the steel plates. This processing usually involves the following steps:

- Base material preparation: Select an appropriate steel plate as the base material and ensure that its quality meets the requirements.

- Surface treatment: Before applying a coating, the surface of the steel plate usually needs to be treated to remove grease, rust, and other impurities to ensure that the coating can adhere firmly to the surface of the steel plate.

- Coating: Select appropriate coating materials, such as zinc, aluminum, polymer, etc., and apply coating on the surface of the steel plate according to the required performance characteristics and application environment. This can be achieved by spraying, dipping, electroplating, etc.

- Drying/curing: The coated steel plate is fed into a drying oven or curing oven to cure the coating and ensure a strong bond with the substrate.

- Cutting/Cutting: Cut the coated steel plate into the required size and shape according to the customer’s needs.

- Packaging/Shipping: Pack the finished product and transport it according to the order requirements to ensure that the product reaches the customer safely.

These steps may vary depending on the coated steel product and production process, but generally, these are the basic steps in the production and processing of coated steel. If you have any questions about the manufacturing process of coated steel, you can contact us directly!