Galvalume Steel

Galvalume Steel Suppliers and Manufacturers Huaxiao Metal supplies galvalume steel, which combines the durable properties of aluminum, silicon, and zinc to provide excellent rust resistance.

24/7 Customer Support

24/7 Customer Support

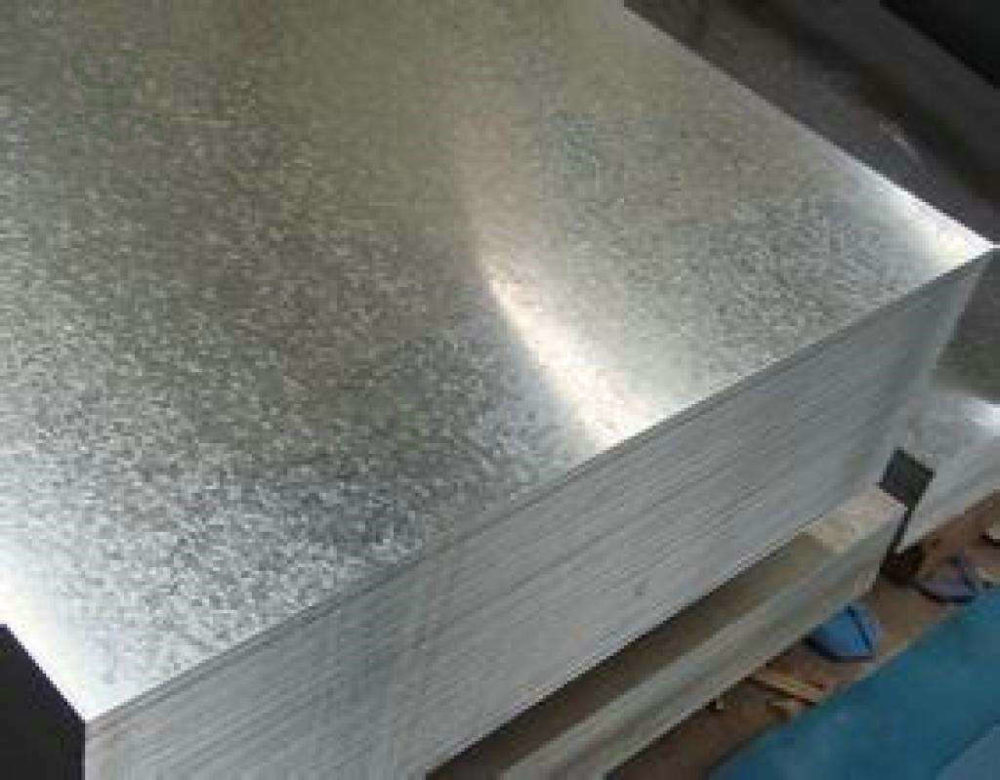

Galvanized sheet is one of the most commonly used sheet types in manufacturing. Many steelmakers and fabricators will tell you that galvanizing is one of the best protections against corrosion. Our company often exports galvanized sheets to all over the world. If you also need it, please contact us for a quote!

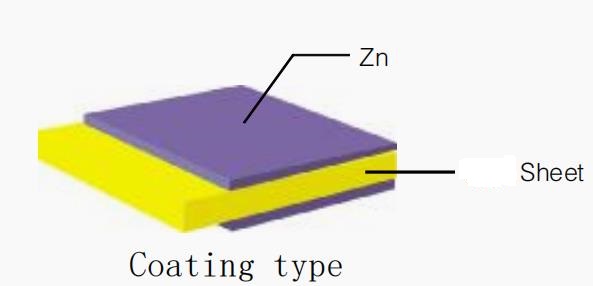

The galvanized metal sheet is a sheet or coil of carbon steel coated with a layer of zinc to prevent corrosion. This process is called galvanizing and involves immersing the steel in a bath of molten zinc or coating it with zinc through electroplating. The result is a protective zinc coating that creates a barrier between the steel and the surrounding environment.

Unleash Precision and Durability with Our Premium Galvanized Sheet Metal for Sale!

Galvanized sheet metal is commonly used in various industries and applications due to its corrosion resistance and durability. It offers several benefits, including:

Corrosion Resistance: The zinc coating on galvanized sheet metal acts as a sacrificial layer. When the sheet metal is exposed to moisture, chemicals, or other corrosive elements, the zinc corrodes first, protecting the underlying steel from rust and corrosion.

Longevity: Galvanized sheet metal has a longer lifespan compared to untreated steel. It can withstand harsh environmental conditions, making it suitable for outdoor applications such as roofing, fencing, and outdoor structures.

Easy Maintenance: Galvanized sheet metal requires minimal maintenance. The zinc layer continues to provide protection even if it gets scratched or damaged, reducing the need for frequent painting or coating.

Versatility: Galvanized sheet metal is available in various thicknesses and can be formed into different shapes and sizes, making it versatile for use in construction, automotive, agricultural, and industrial applications.

Common uses of galvanized sheet metal include roofing materials, gutters, downspouts, ductwork, culverts, automotive body panels, fencing, and structural components. It is valued for its combination of strength, corrosion resistance, and cost-effectiveness, making it a popular choice in many industries where protection against rust and corrosion is essential.

Applications for galvanized steel include:

Roof and Wall Materials: Galvanized steel is often used on roofs and walls of buildings to provide long-lasting protection against corrosion, especially in outdoor environments.

Pipes and Pipe Fittings: Pipes and pipe fittings used to transport liquids and gases are often made of galvanized steel to extend their service life and reduce corrosion.

Metal Railings and Fences: Galvanized steel sheets can be used to make railings, fences, and guardrails for structures such as fences, stairs, and bridges to ensure their durability and appearance.

Coolers and Air Conditioning Systems: Galvanized steel sheets are commonly used to manufacture components in coolers, air conditioning units, and ventilation systems to cope with humid and corrosive environments.

Automotive Parts: Galvanized steel sheets are widely used in the automotive industry to manufacture body parts, exhaust systems, chassis components, etc. to enhance their durability and rust-proof properties.

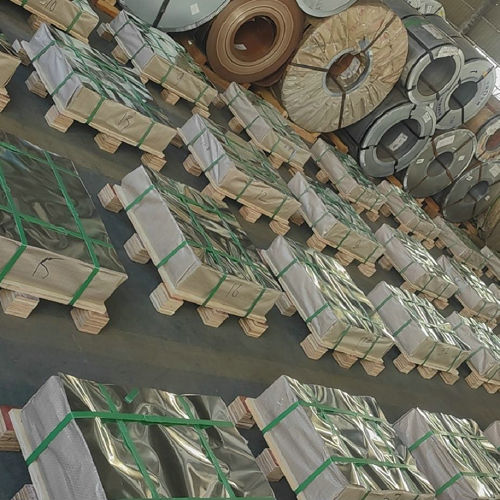

Looking Forward to Becoming One of Your Galvanized Metal Sheets Suppliers

Galvanized Metal Sheets packaging pictures above are the packaging details of our company’s previous exports to Canada. If customers have other packaging requirements, we can meet them.

Galvanizing is an anti-corrosion treatment that can be applied to different types of materials, including steel and other metals. There are different types of galvanizing depending on the method and purpose of galvanizing. Here are some common types of galvanizing:

Hot-Dip Galvanizing: This is one of the most common galvanizing methods. In hot-dip galvanizing, steel is immersed in heated molten zinc to form a uniform zinc coating. This type of galvanizing is commonly used on steel structures, pipes, railings, roofing materials, etc.

Electrogalvanizing: Electrogalvanizing is a method of attaching a zinc layer to the steel surface through an electrochemical process. This method is typically used for smaller parts and products with special surface requirements.

Hot-Dip Galvalume: This is a hybrid coating where aluminum and zinc are coated together on steel. It provides increased corrosion resistance and is commonly used in applications such as metal roofing and siding.

Galvanized Wire: Galvanized steel wire is often used in the manufacture of metal mesh, railings, steel ropes and other products to provide corrosion resistance.

Sherardizing: This is a less common galvanizing method that involves attaching zinc powder to the metal surface at high temperatures. It is often used in special applications such as bolts, nuts and other machine parts.

Each type of galvanizing has different characteristics and suitability, and the choice of galvanizing type often depends on the material’s use, environmental conditions and performance requirements. Regardless of the type of galvanizing used, it is designed to protect the metal from the effects of corrosion and oxidation.

Galvalume Steel Suppliers and Manufacturers Huaxiao Metal supplies galvalume steel, which combines the durable properties of aluminum, silicon, and zinc to provide excellent rust resistance.

Tin Plate Factory and Manufacturer For decades, Huaxiao Metal has been supplying high-quality tinplate and tin coated steel in a variety of specifications, coating weights,

Hot Dip Galvanized Suppliers and Manufacturers Huaxiao Metal offers a wide range of hot-dip galvanized steel plates, pipes, and angles, and customizes specifications according to

Metal Colored Stone/Rainbow Roof Tiles Manufacturers Our premium metal colored stone and rainbow roof tiles combine modern design with exceptional durability to add a unique

Electro Galvanized Steel (EGI) Suppliers Electro-galvanized steel, often abbreviated as EG or EGI, is a type of steel that has undergone a special electroplating process

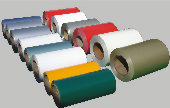

PPGI/PPGL/PPGF Steel Suppliers Are you looking for PPGI/PPGL/PPGF Steel Suppliers? Our company provides high-quality and competitively priced PPGI (pre-painted galvanized steel), PPGL (pre-painted galvanized steel),

WhatsApp us