Hot Dip Galvanized Suppliers and Manufacturers

Huaxiao Metal offers a wide range of hot-dip galvanized steel plates, pipes, and angles, and customizes specifications according to customer needs. Contact us now to get professional advice and the latest hot-dip galvanized product quotes!

Hot Dip Galvanized Product Price, please free to contact us.

Huaxiao Metal hot dip galvanizing line with a designed annual production capacity of 380,000 tons can produce hot dip galvanized steel and hot dip galvalume steel. Huaxiao Metal has produced excellent corrosion-resis-tance hot dip galvanized (galvalume) steel with the process of advanced electrolytic cleaning, automatic scraper cleaning, online coating weight monitoring systems, anti-fingerprint/environmental passivation roller coating, which are widely used in household appliances, construction, door, process instrumentation, and automotive industries.

Coated Sheet are classified into

Hot dip galvanized (GI) Sheet and Strip

Standard steel grades of Janpan, Europe and USA norm, eg. DX51D~DX56D,S220GD~S550GD,H180YD~H300YD,H260LAD~H420LAD,BH220+Z,H450DPD+Z,H600DPD+Z,SGCC,SGC400,

CSTYPEA+Z,CSTYPEB+Z,etc.

Looking Forward to Becoming One of Your Hot Dip Galvanized Product Suppliers

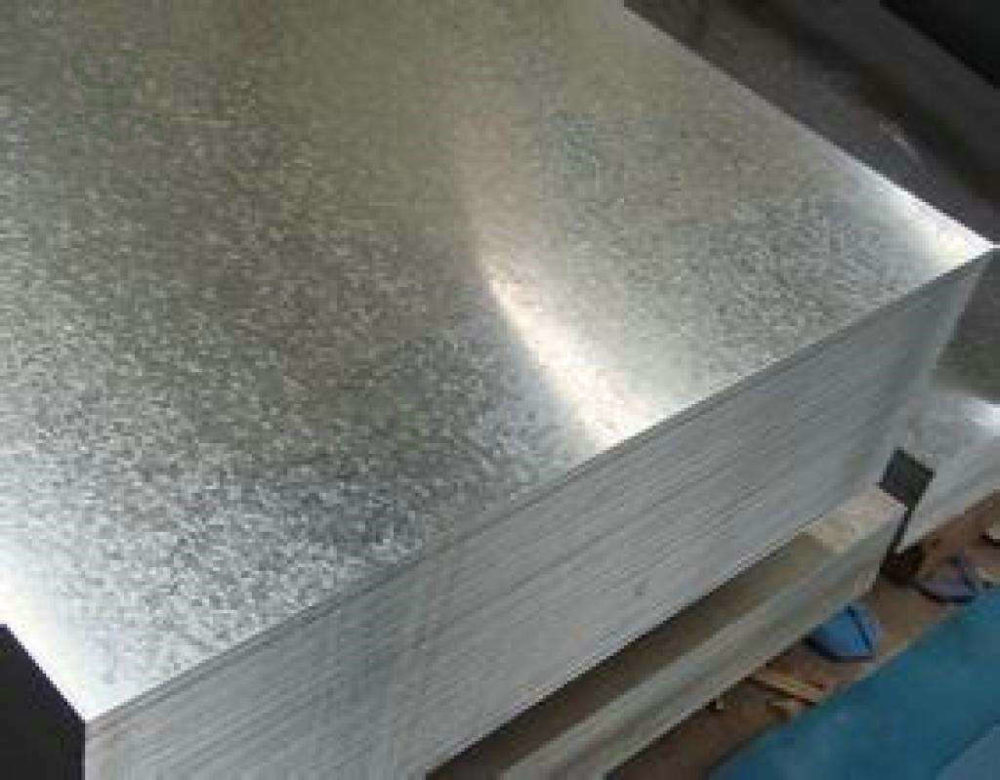

Hot Dip Galvanized (GI) Sheet

Grade and Application of Hot Dip Galvanized

Hot dip galvanized sheet of LY Steel are produced from cold rolled substrate with various strength and thick-ness, hot dipped on two surfaces with a layer of metal zinc to prevent corrosion, which features in the perfor-mance of Zn electrochemical protection.

| Steel grades | Application | Features | Executive norms |

| DX51D+Z | Common bending and formability | The product features in good ductility, apply for simple forming, bending and welding. | EN 10346-2009 |

| CSTYPEB+Z | ASTM A653/A653M-09a | ||

| CSTYPEA+Z | |||

| SGCC | JIS G3302-2010 | ||

| DX52D+Z | DQ | The product features in fine formability, apply to spare parts by drawing | EN 10346-2009 |

| DX53D+Z | DDQ | The product features in excellent deep-drawing performance and good ductility, apply to spare parts by deep-drawing and complex forming | |

| DX54D+Z | EDDQ | The product features in better ductility than DDQ, apply to spare parts by EDDQ and more complex forming. | |

| DX56D+Z | |||

| S220GD+Z | Structural | The product features in high strength with normal processability, apply for simple forming, bending and welding. | |

| S250GD+Z | |||

| S280GD+Z | |||

| S320GD+Z | |||

| S350GD+Z | |||

| S550GD+Z | |||

| H450DPD+Z | dual-phase steel | It has good resistance to corrosion fatigue wear and corrosion resistance, have higher strength and fatigue strength, good weldability, cracking tend to be small. | EN 10346-2009 |

| H600DPD+Z | |||

| H260LAD+Z | high-strength steel | Steel strength can be obviously improved, good machinability and corrosion resistance. | EN 10346-2009 |

| H300LAD+Z | |||

| H340LAD+Z | |||

| H380LAD+Z | |||

| H420LAD+Z | |||

| LGAF+Z | Chrome-free | Excellent fingerprint resistance and lubricity, can be undercoatofthickcoating | Technical standard on fingerprint resistance |

| LGDG1+Z | Rail steel | Excellentrollformingpropertyandsaltsprayproperty,canbe appliedonguiderailandsliderail | Technical standard on rail steel |

| LGDG2+Z | |||

| LGDG1+Z2 | |||

| H180YD+Z | IF high strength | HighstrengthIFsteelwithgooddeepdrawabilityandstrength wasappliedinautomotivecomponentprocessing. | EN 10346-2009 |

| H220YD+Z | |||

| H260YD+Z | |||

| H300YD+Z | |||

| SGC340 | Structural application | The product features in high strength with normal processability, apply for simple forming, bending and welding. | JIS G3302-2010 |

| SGC400 |

Looking Forward to Becoming One of Your Hot Dip Galvanized Product Suppliers

Surface Quality

| Grading | Code | Features |

| Common surface | FA | Detective surface is allowable, eg. Checkered bumps, dent, scratches, blisters, different micro-structure, dark spots, stripes and small passivation spots, etc. as well as tension levelling marks and zinc fluctuation marks. Cracks and slip lines is possible. |

| Fine surface | FB | FB could be reached after skin pass. Small-scale imperfection is allowable, eg. tension levelling marks, skin pass marks, slight scratches, surface structure, zinc fluctuation marks and passivation defect. |

| Excellent surface | FC | FB could be reached after skin pass. Non of any adverse effect of the higher-quality side on aspect after painting, the other surface shall meet the requirement of FB at least. |

Recommended Standard Coating Weight

| Coating pattern | Pure zinc coating |

| Uniform thickness | Z60/Z80/Z100/Z120/Z150/Z180/Z220/Z250/Z275 |

| Differential thickness | Each side:30,40,50,60,75,90,110,125,130,150 |

| Remark: The coils with other coating weight could be supplied through negotiation between the supply and demand sides. | |

Looking Forward to Becoming One of Your Hot Dip Galvanized Product Suppliers

Coating Thickness

| Coating thickness | Pure zinc coating |

| Uniform thickness | 30/30~135/135 |

| Differential thickness | 30~150(each side) |

| Remark: The maximum thickness difference ratio of differential thickness is 1:3. | |

Surface Post-Processing

| Surface processing | Explanation |

| Chromatizing | To prevent exposed to moisture, corrosive risk less during transporation and storage. Local color spots on surface is possible after chromatizing, without affecting any product quality. |

| Chromate-free passivation | To prevent exposed to moisture, corrosive risk less during transporation and storage. The processing is characterized by the satisfaction of environment protection requirements. |

| Oiling | Surface early corrosive risk less, to prevent corrosion during transporation and storage. |

| Chromatizing + oiling | Double antiseptic of chromatizing and oiling |

| Chromate-freepassivation+ oiling(GI) | Double antiseptic of chromate-free passivation and oiling with satisfaction of environment protection requirements |

| Chromate-free anti-finger print (GL) | One razor-thin layer of organic coating on surface provides additional anti-corrosion protection as well as finger print resistance, which could improve lubricating property during forming and act as basement of subsequent coatings with satisfaction of environment protection requirements. |

| Remark: Mixed processing of GI and GL is applied for the surface without identifying GI or GL. | |

Looking Forward to Becoming One of Your Hot Dip Galvanized Product Suppliers

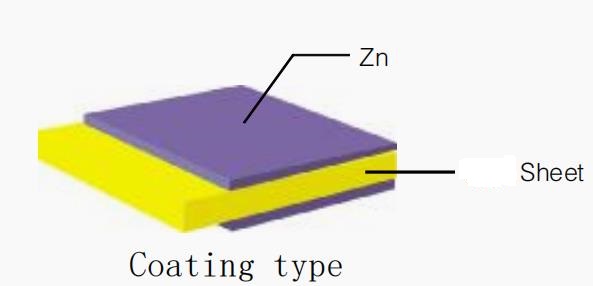

Performane of GI Product

| Product | GI | |

| Coating type | ||

| Processability |

| |

| Thermotolerance | Non-discoloring for long term use at 230℃ , but color change in exceed of 250℃ | |

| Corrosion resistance | The electrochemical protection of GI coating on steel is better than that of oil paint and plastic layer, higher collision-resistance and scratch-resistance without peeling off for decades. | |

| Coating | Smooth coating film could be obtained through selection of zinc spangle |

Looking Forward to Becoming One of Your Hot Dip Galvanized Product Suppliers

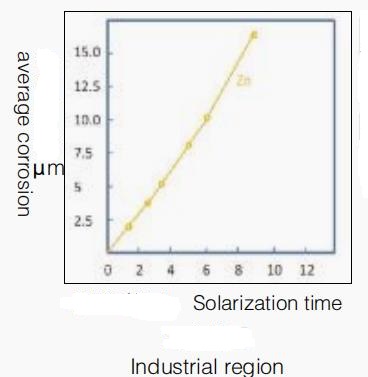

Anti-Corrosion Property

| Test time | 350h | 1200h | 350h | 1200h |

| Galvanizing type and weight | GI,90/90g/m | |||

| Test standard | ASTM B117 | |||

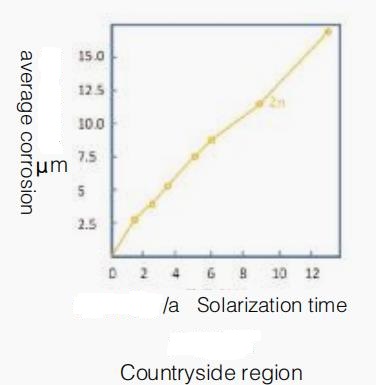

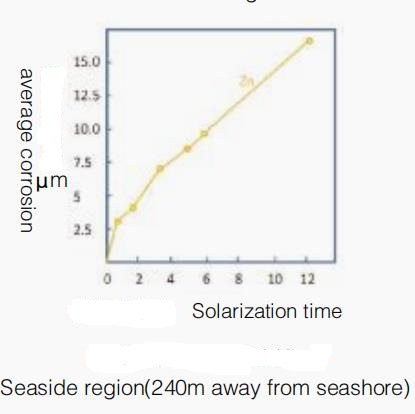

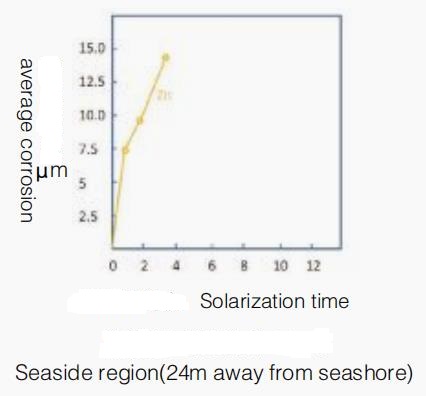

Air Exposed Test

Looking Forward to Becoming One of Your Hot Dip Galvanized Product Suppliers

Electro Galvanized VS Hot Dip

Electro-galvanization and hot-dip galvanization are two different methods of applying a protective zinc coating to steel or iron to prevent rusting. Both processes offer distinct advantages and are used in different applications depending on the specific requirements. Here’s a breakdown of the two processes:

Electro Galvanization:

- Electro galvanization is a process that involves using electrolysis to coat a metal surface with a thin layer of zinc.

- It is generally used for indoor applications or products that won’t be exposed to harsh environmental conditions.

- The electro-galvanized coating is thinner than hot-dip galvanized coating.

- The process offers a smooth and shiny finish that is visually appealing.

- It provides excellent corrosion protection but may not be as durable as hot-dip galvanization.

Hot-Dip Galvanization:

- Hot-dip galvanization is a process where steel is dipped into a bath of molten zinc at a temperature of around 450°C.

- The process results in a thicker layer of zinc coating compared to electro-galvanization, providing better protection against corrosion and rust.

- It is used for outdoor applications, particularly in environments where the steel is exposed to harsh weather and corrosive elements.

- Hot-dip galvanized coatings are more durable and can provide long-term protection even in challenging environments.

- The coating tends to have a duller, more matte finish compared to electro-galvanized coatings.

Choosing between electro-galvanization and hot-dip galvanization depends on various factors such as the intended use, environmental conditions, and the level of protection required. Hot-dip galvanization is typically preferred for applications where the steel will be exposed to harsh conditions, while electro-galvanization is suitable for indoor or less demanding applications.

Contact Us For China Hot Dip Galvanized Prices

Coated Steel

Galvalume Steel

Galvalume Steel Suppliers and Manufacturers Huaxiao Metal supplies galvalume steel, which combines the durable properties of aluminum, silicon, and zinc to provide excellent rust resistance.

Galvanized Sheet Metal

Galvanized Sheet Metal Factory and Manufacturer Galvanized sheet is one of the most commonly used sheet types in manufacturing. Many steelmakers and fabricators will tell

Tin Plate

Tin Plate Factory and Manufacturer – Huaxiao Metal For decades, Huaxiao Metal has been supplying high-quality tinplate and tin coated steel in a variety of

Color Stone Metal Tile

Metal Colored Stone/Rainbow Roof Tiles Manufacturers Our premium metal colored stone and rainbow roof tiles combine modern design with exceptional durability to add a unique

EGI

Electro Galvanized Steel (EGI) Suppliers Electro-galvanized steel, often abbreviated as EG or EGI, is a type of steel that has undergone a special electroplating process

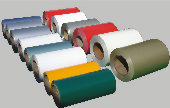

PPGI/PPGL/PPGF

PPGI/PPGL/PPGF Steel Suppliers Are you looking for PPGI/PPGL/PPGF Steel Suppliers? Our company provides high-quality and competitively priced PPGI (pre-painted galvanized steel), PPGL (pre-painted galvanized steel),