[email protected]

24/7 Customer Support

+86-13761906384

24/7 Customer Support

24/7 Customer Support

24/7 Customer Support

For decades, Huaxiao Metal has been supplying high-quality tinplate and tin coated steel in a variety of specifications, coating weights, and conditions for a variety of industrial purposes. Huaxiao Metal’s products combine strength, corrosion resistance, lightweight, and ductility, making them ideal for many precision uses, including food packaging and consumer goods.

No matter your industry or application, we are committed to providing you with the best tinplate and tin coated steel products. Looking forward to becoming one of your tinplate suppliers, you are also welcome to visit our tin plate factory!

Looking for a reliable tinplate supplier or manufacturer? Huaxiao Metal is one of the trusted tinplate suppliers in China, offering competitive prices and a wide range of stock options to meet customer needs. Contact us today to learn more about our tinplate products.

Tinplate is a thin sheet or coil of cold-rolled carbon steel coated with a layer of tin to prevent corrosion and improve its appearance. It is widely used in packaging in various industries, such as the production of food and beverage metal cans.

Huaxiao Metal has been in the tinplate business since 2016. We have become a trusted partner and tinplate expert for many customers. Our long experience in the steel industry has enhanced our capabilities. We have been importing steel from all over the world since 2014s. Our established global network, coupled with our experience in aluminum, stainless steel and carbon steel, makes us your trusted partner, also for tinplate.

As we have connections with several Chinese steel mills, we have enough advantages and strengths, and we look forward to becoming one of your suppliers of tinplate.

As leading tin plate manufacturers, we ensure all our products meet the highest quality standards. With a large stock inventory and flexible prices, we are ready to fulfill your orders quickly and efficiently.

Unleash Precision and Durability with Our Premium Tin Plate Steel for Sale!

Corrosion Resistance: Tinplate is highly resistant to corrosion due to its tin coating, making it ideal for packaging to prevent rust and contamination.

Aesthetic Appeal: It has a shiny, metallic appearance that enhances the visual appeal of products, making it popular for display on store shelves.

Food Safety: Tinplate is non-toxic and safe for contact with food, ensuring the contents of containers remain uncontaminated.

Formability: Tinplate is easily shaped into various packaging designs, providing versatility for different container shapes and sizes.

Recyclability: Tinplate is recyclable, promoting sustainability by being processed and reused to make new products.

Our tinplate steel is manufactured to the highest standards, ensuring excellent corrosion resistance, durability and formability. Whether you need tinplate for packaging, automotive parts or construction, our products can meet your needs. Contact us today to get a quote for your tinplate needs.

Food Packaging: Tinplate is extensively used for food packaging, including cans for vegetables, fruits, meats, and seafood. It helps maintain the freshness and safety of food products while preventing corrosion.

Beverage Cans: Tinplate is used to make beverage cans for carbonated drinks, fruit juices, and alcoholic beverages. The tin coating preserves the taste and quality of the beverages and prevents interaction with the metal.

Aerosol Containers: Tinplate is utilized in the manufacturing of aerosol spray cans for products like deodorants, paints, and household cleaners. Its corrosion resistance ensures that the contents remain uncontaminated.

Cosmetic Packaging: Tinplate is sometimes used for cosmetic containers, particularly for products that require a high-quality, attractive appearance.

Chemical and Industrial Containers: It is used in containers for chemicals, paints, lubricants, and other industrial products due to its resistance to corrosion and durability.

Whether you are a supplier or end-user, our tin plate is available in a variety of sizes and thicknesses to suit your industry needs. Check our stock availability and get competitive pricing today!

Looking Forward to Becoming One of Your TinPlate Suppliers

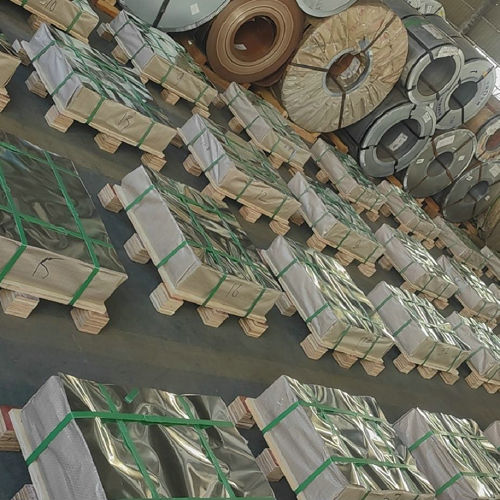

The tin plate & tin coated sheet packaging pictures above are the packaging details of our company’s previous exports to Canada. If customers have other packaging requirements, we can meet them.

Tin plating on cold-rolled carbon steel involves several steps to ensure proper adhesion and a corrosion-resistant coating. Here’s a general overview of the process:

It’s important to note that the specific process parameters, such as plating bath composition, temperature, and plating duration, can vary depending on the desired thickness and quality of the tin coating, as well as the specific requirements of the application. Therefore, it’s advisable to consult with experts or follow industry standards and guidelines for tin plating on cold-rolled carbon steel to achieve the desired results.

As one of the leading tin plate manufacturers, we pride ourselves on providing high quality products at competitive prices. Our extensive inventory ensures fast delivery, making us the first choice for tin plate distributors and businesses.

Huaxiao Metal is your trusted partner. Contact us today to discuss your requirements and get a custom quote.

Huaxiao Metal is your trusted supplier of quality tin plate products. As a leading tinplate factory in China, we specialize in providing high-quality tinplate for a variety of industrial needs. Known for its excellent corrosion resistance, durability, and versatility, our tinplate is well-suited for a variety of applications. Contact us for tinplate prices!

WhatsApp us