Stainless Steel Cold Rolled Sheet/Coil/Strip

As one of the leading manufacturers and suppliers of cold rolled stainless steel sheets/coils/strips in China, we specialize in providing high-standard cold rolled stainless steel products to meet your various needs. Our products, including cold rolled stainless steel sheets, coils, and strips, are strictly quality inspected to ensure excellent surface finish and precise dimensional tolerances.

Whether you need it for construction, automobiles, food processing, or industrial equipment, we can provide the most competitive cold rolled stainless steel sheets/coils/strips prices and provide professional technical support. For detailed specifications and the latest prices of our cold rolled stainless steel products, please contact us directly.

Stainless Steel

Stainless steel Cold Rolled

Grades: 304 304L 310S 316L 321 409L 410S 430 439 441 444 445

Thickness: 0.05-3mm stainless steel

Width: 4-2000mm

Finish: 2B,2D, BA, No.3, No.4, No.5, SB, HL, etc.

Type: Stainless Steel Sheet, Stainless Steel Coil, Stainless Steel Strip

Huaxiao Metal is a leading cold rolled stainless steel supplier offering the best prices and services. We can process orders of any specification, length and thickness, then carry out quality inspection and packaging.

Contact us for cold rolled stainless steel prices!

Cold Rolled Stainless Steel Available Specification:

Stainless steel cold rolled Grade/Specification

ASTM: A240 SA24 / S30100 S30400 S30403 S31008 S31603 S32100 S41008 S43000 S43932 S44400 S44500

JIS: G4304 G4305 G4312 / SUS301 SUS304 SUS304L SUS310 SSUS316L SUS321 SUH409L SUS410S SUS420J2 SUS430

AISI: 301 304 304L 310S 316L 321 409L 410S 430 439 441 444 445

EN: 10088-2 17224 17440 17441 / 1.4310 1.4301 1.4306 1.4845 1.4404 1.4541 1.45121 .4000 1.4028 1.4016 1.4509

Mill’s Standard: 201 202 204Cu3 L1 L4

Stainless steel Cold rolled available size

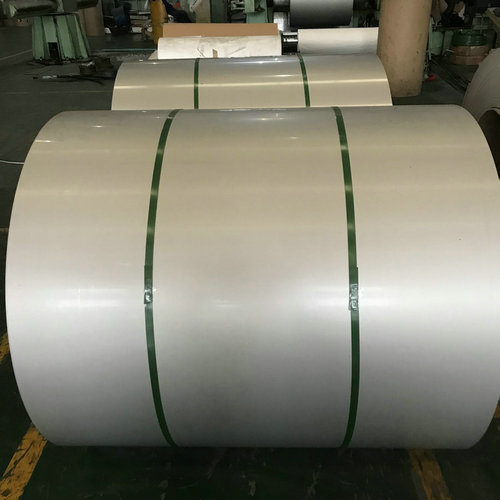

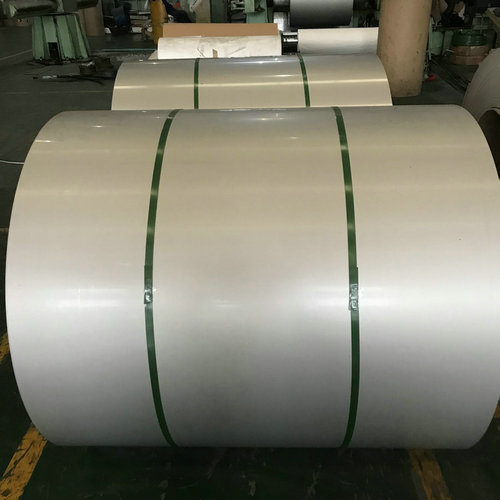

Cold Rolled Stainless Steel Coils

Thickness: 0.05~3.0 mm

Width: 600~2000mm

ID: 610 or 508mm

Finish:2B,2D,BA,No.3,No.4,No.5,SB, HL

Cold Rolled Stainless Steel Strips

Thickness: 0.05~3.0 mm

Width: 4~600mm

ID: 610mm

Finish:2B,2D,BA,No.3,No.4,No.5,SB, HL

Cold Rolled Stainless Steel Sheets

Thickness:0.05~3.0 mm

Width: 914, 1000,1219,1250,1500, 1524, 1800, 2000 mm

Length: 2000,2438,2500,3000,3048,6069,10000

Finish: 2B, 2D, BA, No.3, No.4, No.5, No.8, HL, Etching, SB, Ti-coating

Application of Cold rolled stainless steel

Cold rolled stainless steel is known for its superior surface finish, precise dimensions, and enhanced mechanical properties compared to hot rolled stainless steel. Its smooth surface and tight tolerances make it suitable for various applications where aesthetics and exact specifications are crucial. Here are some common applications:

Architectural and Construction

- Applications: Facade panels, window frames, staircases, and interior cladding.

- Reasons: Cold rolled stainless steel provides an attractive, smooth surface and is highly resistant to corrosion, making it ideal for both functional and decorative elements in buildings.

Automotive Industry

- Applications: Exterior trim, body panels, and interior components.

- Reasons: The material’s smooth surface and excellent finish are important for automotive parts that require both durability and aesthetic appeal. Its corrosion resistance is also valuable for parts exposed to harsh conditions.

Consumer Goods

- Applications: Kitchen appliances, home fixtures, and decorative items.

- Reasons: Cold rolled stainless steel’s refined surface finish and high durability make it ideal for appliances and household items that require a sleek appearance and long-lasting performance.

Industrial Equipment

- Applications: Machinery components, brackets, and precision parts.

- Reasons: Its precise dimensions and smooth surface are crucial for components requiring exact tolerances and consistent quality in industrial settings.

Medical Devices

- Applications: Surgical instruments, diagnostic equipment, and medical implants.

- Reasons: The material’s excellent surface finish and corrosion resistance are essential for maintaining hygiene and ensuring the longevity of medical devices.

Food and Beverage Industry

- Applications: Processing equipment, storage tanks, and food handling surfaces.

- Reasons: Cold rolled stainless steel’s smooth, non-porous surface is ideal for sanitary conditions in food processing and storage, ensuring compliance with health and safety standards.

Electronics and Electrical Applications

- Applications: Electrical enclosures, components, and connectors.

- Reasons: Its smooth finish and resistance to electrical interference make it suitable for housing and components in electronic devices.

Aerospace Industry

- Applications: Aircraft components, structural elements, and landing gear.

- Reasons: Cold rolled stainless steel’s strength-to-weight ratio and precise tolerances are critical for high-performance aerospace applications.

Jewelry and Decorative Items

- Applications: Jewelry, ornaments, and high-end fashion accessories.

- Reasons: The high-quality surface finish and resistance to tarnishing make it a preferred material for jewelry and decorative items that require a polished look.

Railway Industry

- Applications: Train carriages, interior fittings, and track components.

- Reasons: The material’s durability and smooth surface are important for both structural and aesthetic aspects of railway components.

What is Cold rolled stainless steel?

Cold working is performed after hot rolling. It finishes before moving on. Hot rolled stainless steel is drawn again at room temperature for precise dimensions and smooth surfaces.

The cold drawing process includes many processes such as wire drawing, turning, grinding, belt polishing, etc. Cold rolled stainless steel has specified tolerances, finishes, well-defined angles, and edges.

Cold rolled stainless steel is more visually appealing. Yes; it is more expensive due to the extra treatment of cold working. Cold working results in hardness, impact resistance, and distortion.