Aluminum Strip Suppliers and Manufacturers in China

Welcome to Huaxiao Metal! As a company with more than ten years of experience in metal manufacturing and exporting, we are proud to offer high quality aluminum strip products. As an aluminum strip supplier and manufacturer, we are committed to providing our customers with a wide range of options to suit every need. Whether you are in the construction, electronics, automotive or packaging industries, we can provide you with the most suitable aluminum strip solution.

If you are looking for reliable aluminum strip suppliers and manufacturers and have requirements for high quality and competitive prices, please contact us. Huaxiao Metal looks forward to cooperating with you to create a better future!

Aluminum Strip Price, please free to contact us.

- Material: 1070 1100 3003 3004 5052 5754 6061 6063 8021 8079,etc

- Thickness: 0.15-10.0 mm

- Width: 10-600mm

- Temper: F,O,H32,H34,H36,H38,H112,H321,T3,T351,T6,T651,etc.

Aluminum Strip

Aluminum Strip Suppliers | Aluminum Color Strip Manufacturers

A: More than 15 years of experience in aluminum products.

B: OEM and ODM according to customer requirements.

C: Strict quality control.

D: Resources-sufficient supply capacity

E: Capital-sufficient own funds

F: Team–Foreign trade professional team

G: Service-perfect pre-sales and after-sales service

H: Policy advantage-government support

Specification of Aluminium Strip

Item | Best Price Aluminum Strip Roll/Color Coated Aluminum Strip |

Standard | GB/T3190-2008, GB/T3880-2006, ASTB209, JIS H4000-2006, ISO9001,etc |

Material | 1070 1100 3003 3004 5052 5754 6061 6063 8021 8079, etc |

Thickness | 0.15-10.0 mm |

Width | 10-600mm |

Temper | F,O,H32,H34,H36,H38,H112,H321,T3,T351,T6,T651,etc. |

Color | various colors are available, we also can make in accordance with your own color range |

Price term | multiple colors are available, we also can make in accordance with your own color range |

Payment term | L/C, T/T, etc. |

MOQ | 2 tons |

Package | Export standard, covering with plastic film then packed with wooden pallet or wooden case for good price aluminum strip |

Looking Forward to Becoming One of Your Aluminum Strip Suppliers

What is Aluminum Strip Roll/Color Coated Aluminum Strip?

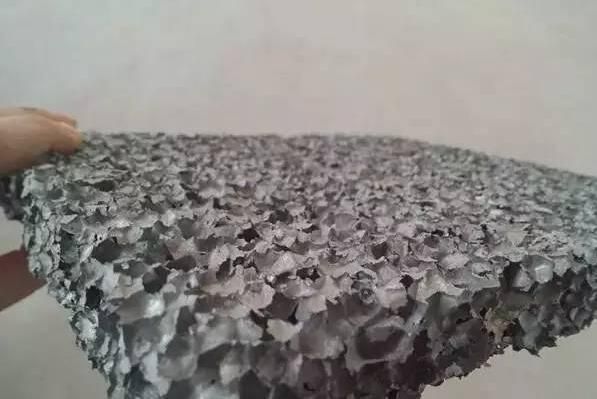

The raw material of the aluminium strip is pure aluminum or aluminum alloy cast-rolled aluminum coil or hot-rolled aluminum coil. It is rolled into a thin aluminum coil of different thicknesses and widths by a cold rolling mill and then slit according to the application.

An aluminum strip is an aluminum alloy with an aluminum content of more than 99.5%. The aluminium strip is made of slitting aluminum coils. Because of its high aluminum content, it is also called a pure aluminium strip in the industry. Because this series of aluminum tapes has good plasticity, corrosion resistance, electrical conductivity, and thermal conductivity. An aluminum strip is more suitable for further stamping, extrusion, and deep drawing processing. Made into various aluminum foil products, and various electronics, lamps, nameplates, and electrical products.

Huaxiao Metal Aluminium Strips - Data Sheet

Mechanical Propeties of Flat Aluminum Strip Roll

| Internal Alloy Design | Former B.S. Specs | 0.2% Proof Stress MPa | Tensile Strength MPa | % Elongation | ||

| On | On | |||||

| √5.65 SO | 50 mm | |||||

| 1050A | 0 | S1B | 35 | 75 | 25 | 32 |

| H18 | 133 | 146 | – | 5 | ||

| 1080A | 0 | S1A | 30 | 75 | – | 32 |

| H18 | 125 | 138 | – | 5 | ||

| 1200 | 0 | S1C | 40 | 80 | 20 | 30 |

| H14 | 115 | 125 | – | 5 | ||

| H18 | 143 | 160 | – | 4 | ||

| 1350 | 0 | P1E | 95 | 85 | – | – |

| H12 | 110 | – | – | 60 | ||

| H14 | 125 | – | – | 70 | ||

| H16 | – | – | 75 | |||

| 2014A | T4 | HS15 | 255 | 410 | 10 | 14 |

| T6 | 420 | 470 | 8 | 7 | ||

| 2024 | T5 | 345 | 480 | – | 18 | |

| T4 | 325 | 470 | – | 20 | ||

| 3003 | 0 | 45 | 110 | 32 | ||

| H14 | 160 | 170 | 7.5 | |||

| H16 | 180 | 200 | 4.5 | |||

| H18 | 235 | 260 | 4 | |||

| 3103 | 0 | NS3 | 50 | 112 | – | 24 |

| H14 | 140 | 157 | – | 5 | ||

| H18 | 185 | 195 | – | 4 | ||

| 5005 | 0 | NS41 | – | 120 | – | 30 |

| H14 | 115 | 165 | – | 8 | ||

| H18 | 170 | 195 | – | 5 | ||

| 5052 | 0 | 90 | 200 | 22.5 | ||

| H22 | 180 | 240 | 18.5 | |||

| H24 | 220 | 260 | 9.5 | |||

| H26 | 240 | 270 | 8.5 | |||

| H28 | 260 | 300 | 8 | |||

| 5083 | 0 | NS8 | 140 | 292 | 20 | 16 |

| H22 | 250 | 337 | – | 8 | ||

| H24 | 285 | 375 | – | 6 | ||

| 5086 | 0 | 115 | 260 | 22 | ||

| H22 | 205 | 290 | 12 | |||

| H24 | 255 | 325 | 10 | |||

| 5558 | 0 | 169 | 270 | 14 | 16.5 | |

| 5154A | 0 | NS5 | 105 | 245 | 20 | 16 |

| H22 | 185 | 270 | – | 7 | ||

| H24 | 240 | 300 | – | 6 | ||

| 5251 | 0 | NS4 | 87 | 180 | 20 | 18 |

| H22 | 150 | 220 | – | 6 | ||

| H24 | 190 | 250 | – | 5 | ||

| 5454 | 0 | NS51 | 100 | 250 | 20 | 16 |

| H22 | 200 | 277 | – | 7 | ||

| H24 | 225 | 297 | – | 5 | ||

| 5558 | 0 | 270 | 169 | 14 | 16.5 | |

| 5754 | 0 | 120 | 230 | 20 | – | |

| 6061 | T4 | HS20 | 125 | 215 | 18 | 16 |

| T6 | 265 | 305 | 11 | 9 | ||

| 6082 | T4 | HS30 | 130 | 225 | 16 | 15 |

| T6 | 270 | 310 | 9 | 8 | ||

| 7020 | T4 | HS17 | 200 | 310 | 12 | 10 |

| T6 | 290 | 350 | 10 | 8 | ||

| 7022 | T6 | 475 | 530 | 9 | – | |

| 7075 | T6 | 505 | 570 | 10 | 11 | |

| Internal Alloy Design | Shear Strength MPa | Fatigue Strength 50 mil. cycles MPa | Hardness | |||

| Brinell | Vickers | Rockwell B | ||||

| 1050A | 0 | 50 | 20 | 21 | 22 | – |

| H18 | 78 | 45 | 40 | 43 | – | |

| 1080A | 0 | 60 | – | 19 | 20 | – |

| H18 | – | – | 38 | 40 | – | |

| 1200 | 0 | 70 | 40 | 22 | 23 | – |

| H14 | 85 | 55 | 33 | 35 | – | |

| H18 | 100 | 76 | 42 | 45 | – | |

| 1350 | 0 | 55 | – | – | – | – |

| H12 | – | – | – | – | – | |

| H14 | – | – | – | – | – | |

| H16 | – | – | – | – | – | |

| 2014A | T4 | 262 | 170 | 115 | 122 | 67.3 |

| T6 | 293 | 170 | 145 | 153 | 81 | |

| 2024 | T5 | 280 | 140 | 120 | 126 | 69.8 |

| T4 | 280 | 140 | 120 | 126 | 69.8 | |

| 3003 | 0 | 80 | 50 | 28 | ||

| H14 | 100 | 60 | 40 | |||

| H16 | 100 | 70 | 47 | |||

| H18 | 110 | 70 | 55 | |||

| 3103 | 0 | 76 | 54 | 29 | 30 | – |

| H14 | 92 | 71 | 44 | 47 | – | |

| H18 | 108 | 85 | 53 | 56 | – | |

| 5005 | 0 | 76 | – | 28 | 29 | – |

| H14 | 96 | – | 40 | 42 | – | |

| H18 | 110 | – | 50 | 52 | – | |

| 5052 | 0 | 125 | 110 | 47 | 50 | |

| H22 | 140 | 120 | 60 | 63 | ||

| H24 | 145 | 125 | 67 | 71 | ||

| H26 | 160 | 130 | 74 | 78 | ||

| H28 | 165 | 140 | 80 | 84 | ||

| 5083 | 0 | 155 | 124 | 72 | 76 | – |

| H22 | – | – | 95 | 100 | 52.5 | |

| H24 | – | – | 110 | 116 | 63.6 | |

| 5086 | 0 | 160 | ||||

| H22 | ||||||

| H24 | 185 | |||||

| 5558 | 0 | 143 | – | 75 | 82 | – |

| 5154A | 0 | 146 | – | 55 | 58 | – |

| H22 | 170 | 139 | 83 | 87 | 40 | |

| H24 | – | 148 | 95 | 100 | 52.5 | |

| 5251 | 0 | 125 | 92 | 45 | 47 | – |

| H22 | 124 | 62 | 65 | – | ||

| H24 | 139 | – | 70 | 74 | – | |

| 5454 | 0 | 159 | – | 62 | 65 | – |

| H22 | 165 | – | 73 | 77 | – | |

| H24 | 179 | – | 81 | 85 | – | |

| 5558 | 0 | 143 | – | 75 | 82 | – |

| 5754 | 0 | 155 | – | 60 | 62 | – |

| 6061 | T4 | 165 | 95 | 60-70 | 64-74 | 48-56.6 |

| T6 | 205 | 95 | 90-100 | 95-105 | – | |

| 6082 | T4 | 178 | 106 | 60-70 | 64-74 | 48-56.6 |

| T6 | 218 | 124 | 90-100 | 95-105 | – | |

| 7020 | T4 | – | – | 95 | 100 | 69.8 |

| T6 | – | – | 120 | 126 | – | |

| 7022 | T6 | 310 | 159 | 145 | 153 | – |

| 7075 | T6 | 330 | 160 | 150 | 157 | 82.4 |

Looking Forward to Becoming One of Your Aluminum Strip Suppliers

Aluminum Strip Features

1) Light weight, high strength, excellent rigidity, and superior impact resistance

2) Excellent surface flatness and smoothness

3) Heat insulation, sound insulation, fire prevention

4) Acid resistance, alkali resistance, good weather resistance, no resonance

5) All colors are uniform, easy to process and make, and quick to install

6) Elegant and gorgeous, good flexibility, suitable for various designs

7) Convenient maintenance and simple cleaning

Aluminium Strip Applications

Aluminium strip roll is widely used in the following fields: cosmetic packaging, lamp base, caps, transformer, fin radiator, heater, aluminum-plastic composite pipes, cables, optical cables, blinds, etc.

Contact Us for Stainless Steel Strip Price

Huaxiao Aluminum Metal Products

As a global aluminum metal supplier and manufacturer, Huaxiao offers a wide range of aluminum steel products for all your needs. Explore some of our most popular steel products.