Medium and High Carbon Steel Suppliers & Manufacturers

At Huaxiao Metal, we are committed to being a trusted supplier of medium and high carbon steel, providing high quality products, competitive prices and global shipping services. Reasons to choose us include:

Abundant Inventory: We have a rich inventory of medium and high carbon steel to meet your needs.

Custom Sizes and Grades: Provide customized solutions according to customer specifications.

Professional Support: Our professional team is always available to provide you with carbon steel product selection and technical support.

Medium and High Carbon Steel Price, please free to contact us.

Medium and High Carbon Steel

Difference in Carbon Content

Medium Carbon steel

About 0.3–0.5% carbon content. Balances ductility and strength with good wear resistance; used for large parts, forgings, and auto parts.

High Carbon steel

The carbon content is approximately 0.6% to 1.0%. Very strong for springs, knives, and high-strength wires.

Ultra-High Carbon Steel

About 1.25–2.0% carbon content. Steel that can be tempered to high hardness. For special purposes such as (non-industrial) knives, shafts, and punches. Most steels containing more than 2.5% carbon are manufactured using powder metallurgy.

For more information on carbon steel metal, contact Huaxiao Metal Steel.

Delivery standard

Type | Application | Technical agreement | |

Family | Grade | ||

Saw steel | 75Cr1、SKS51、80CrV2、65Mn、 50Mn2V、30CrMo | Stone, metallurgy, and woodworking saw etc | GB/T 24181、 JIS G4404、EN 10132-4 |

Carbon structural steel | 20#-85#、20Mn-70Mn、 SAE1020- 1086、S20C-58C、 C20-C60、C55S-95S | Auto parts, tool, knife, saw | GB/T 699、SAE J403 、 JIS G4051、EN 10132-4 |

Carbon tool steel | T8-T10、SK85、SK95 | Tool, knife, saw | GB/T 1298、JIS G4401 |

Alloy structural steel | 51CrV4、16MnCr5、 SCM415-445、 30CrMo-42CrMo 20Mn2-50Mn2、10SiMn2、 20MnB5-38MnB5 | auto parts, tool, knife, saw, high strength strap, agriculture machinery | GB/T 3077、EN 10089、 JIS G4053、technique specification |

Alloy tool steel | 55MnB、SKS51、80CrV2、 SAE8660、D6A、X32 | Tool, knife, saw blade | JIS G4404、 ASTM A29/A29M |

Bearing steel | GCr15 | Wear resistant steel pipe | GB/T 18254 |

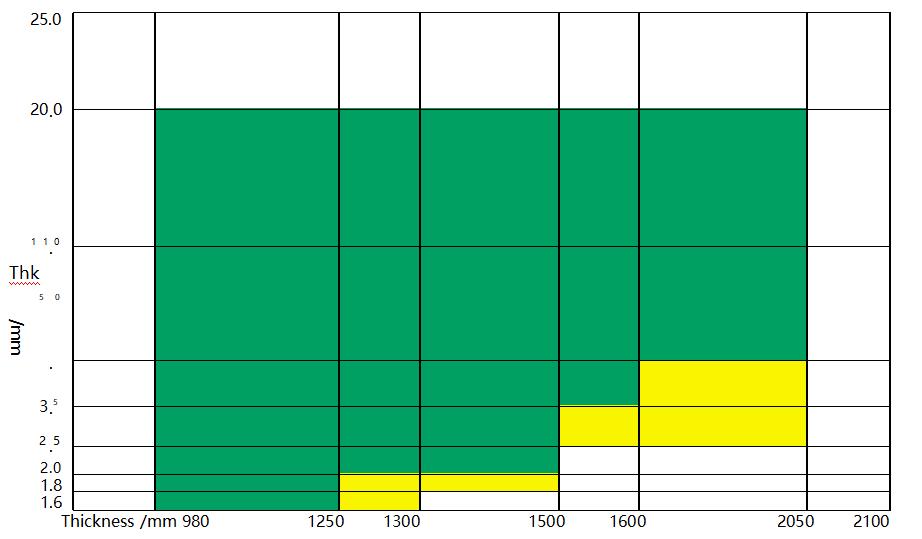

Available Scope

Remark: the green area is the normal production area, and the yellow area is the dimension that must be determined whether it can be produced after the audit.

Application and Features

The medium and high carbon steel (0 .25- 1 .0% C)is of full specifications with high toughness, high harden-ability, and high wear-resistance, which are widely used in saw blades (stone, metallurgy, and woodworking), automotive parts (disk spring, safety lock, hose clamp, seat、gear), cutter, tool, and high strength strapping band, etc. The sheet thickness covers 1.6~20mm with a width range of 980~2050mm.

The medium and high carbon steel guarantee that the Rockwell hardness (HRC) is between 18~26 so that the turn-down edge due to over softness shall not be generated, tearing due to hard is also impossible during the processing of saw blade basement. The product performs good plasticity and can be used for automotive or tractor clutch, the high reduction can be implemented during cold rolling process.

With a good profile and high dimension accuracy, the product higher than 3.9mm in thickness can be decoiled in the most advanced domestic cut-to-length line, which guarantees good flatness, i.e, unfitness of decoiled/sheet <10mm/m. The unflatness of the product with thickness lower than 3mm can be guaranteed as < 15mm/m after standrad decoiling through finishing.

The ultra-thin 1.6mm and ultra-wide 2050mm hot rolled wide strip or sheet can be supplied .

The medium and high carbon steel can be batch annealed by coil or roller hearth annealed by sheet .

Contact Us for Medium and High Carbon Steel Prices

Looking for high-quality and affordable medium and high carbon steel products? Contact us now to get a quote, and learn about our stock availability and custom solutions.

Huaxiao Metal is one of your trusted carbon steel suppliers in China. Contact us for pricing information or more details about stock availability.