In the world of metal packaging, choosing the right material is critical for product safety, durability, and brand presentation. Two of the most prominent materials in the industry are tinplate vs electrolytic tin-free steel. While they may look similar to the untrained eye, their composition, properties, and ideal applications differ significantly.

As a leading supplier, Huaxiao Metal understands that making the right choice impacts everything from your production process to your bottom line. This comprehensive guide will break down the key differences between tinplate and TFS to help you select the perfect material for your needs.

Tin Plate

Tin Plate Factory and Manufacturer – Huaxiao Metal For decades, Huaxiao Metal has been supplying high-quality tinplate and tin coated steel in a variety of

At Huaxiao Metal, we supply both high-quality tinplate and electrolytic tin-free steel to meet various industry needs. In this article, we’ll explore the key differences between these two materials to help buyers make informed sourcing decisions.

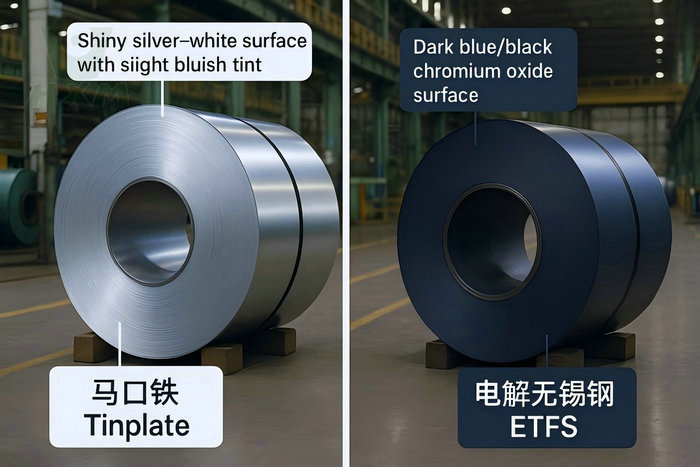

Key Differences: Tinplate vs Electrolytic Tin-Free Steel

| Feature | Tinplate (ETP) | Tin-Free Steel (TFS / ECCS) |

| Coating | A layer of pure tin is electroplated onto a steel base. | A layer of metallic chromium and chromium oxide. |

| Corrosion Resistance | Excellent. The tin layer provides a strong protective barrier. | Good, but generally requires a lacquer coating for best results. |

| Weldability | Excellent. Ideal for manufacturing three-piece welded cans. | Poor. Not suitable for welding; used for cemented or drawn cans. |

| Paint Adhesion | Good. | Excellent. Superior to tinplate, ideal for decorative applications. |

| Cost | Higher, due to the cost of tin as a raw material. | More economical, providing a cost-effective alternative. |

| Appearance | Bright, reflective metallic luster. | A duller, unique metallic luster characteristic of chromium. |

What is Tinplate (Electrolytic Tinplate - ETP)?

Tinplate is, simply put, a thin steel sheet coated with a layer of tin. This electrolytic plating process creates a material that combines the strength and formability of steel with the corrosion resistance and lustrous appearance of tin.

Key Advantages of Tinplate:

Superior Corrosion Resistance: The tin coating acts as a robust barrier, protecting the steel base from rust and preventing interaction with the contents, making it a top choice for food and beverage packaging.

Excellent Weldability & Formability: Tinplate can be easily soldered and welded, which is essential for the integrity of three-piece cans (like those for powdered milk or vegetables).

Aesthetic Appeal: Its bright, clean finish provides a premium look and an excellent substrate for printing and decoration.

Common Applications:

Tinplate is the go-to material for food cans, beverage cans, aerosol containers, paint cans, and decorative tins.

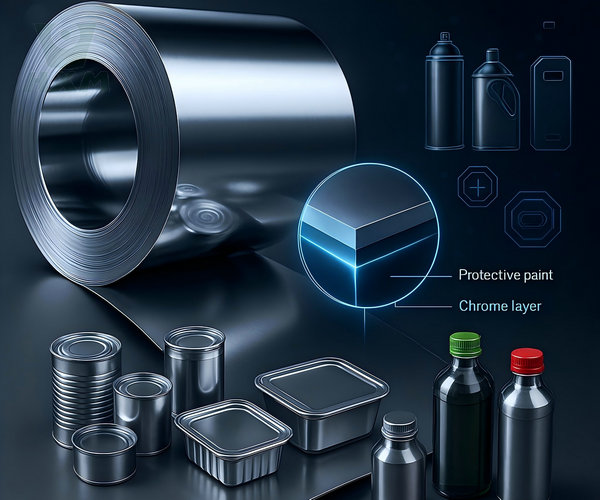

What is Tin-Free Steel (Electrolytic Chromium Coated Steel - ECCS)?

Tin-Free Steel, also known as TFS or ECCS, was developed as a more economical alternative to tinplate. Instead of tin, it features a very thin, electroplated layer of metallic chromium and chromium oxide over the steel base.

Key Advantages of Tin-Free Steel:

Exceptional Paint Adhesion: The surface of TFS offers outstanding adhesion for paints, lacquers, and inks. This makes it the perfect choice for products requiring high-quality, complex decorations and coatings.

Heat Resistance: TFS maintains its properties at high temperatures, making it suitable for processes like baking and sterilization.

Sulfide Stain Resistance: It shows strong resistance to black sulfide staining, which can occur with protein-rich foods like fish, making it a preferred material for tuna and seafood cans.

Cost-Effectiveness: With chromium being less expensive than tin, TFS offers a significant cost advantage for many applications.

Common Applications:

TFS is widely used for bottle caps, can ends, two-piece drawn-and-redrawn (DRD) cans, fish cans, and various industrial components.

Tinplate vs Electrolytic Tin-Free Steel: Which Should You Choose?

The decision between tinplate and TFS ultimately depends on your product and production process.

Choose Tinplate if: Your primary requirement is weldability. If you are manufacturing three-piece cans that require a welded side seam, tinplate is the only suitable option. It is also the best choice when maximum, uncoated corrosion resistance is needed.

Choose Tin-Free Steel (TFS) if: Your application relies on superior paint adhesion and you do not require welding. For bottle caps, twist-off lids, can ends, and two-piece cans, the excellent lacquer adhesion and cost savings of TFS make it the ideal choice.

Both tinplate and Tin-Free Steel are exceptional materials that have revolutionized the packaging industry. There is no single “better” option—only the “right” option for a specific application. Tinplate excels in weldability and raw corrosion resistance, while TFS leads in paint adhesion and cost-efficiency.

Ready to boost your packaging performance with the right material?

At Huaxiao Metal, we specialize in providing premium tinplate solutions tailored to your exact specifications. Our team of experts is ready to help you navigate the complexities of metal packaging to ensure you get the best performance and value.

Contact us today to discuss your project requirements, get a competitive quote, and let our experts guide you to the perfect tinplate solution for your business.

Tinplate and TFS at Huaxiao Metal

As a trusted tinplate supplier and manufacturer, Huaxiao Metal offers:

Prime-quality tinplate and electrolytic tin-free steel

Wide range of thicknesses, widths, and temper grades

Custom slitting and shearing

Export-ready packaging and fast delivery

💬 Interested in our Tinplate or TFS products?

Feel free to contact us for the latest prices, specifications, or a free quote. We welcome bulk orders and international inquiries.

FAQ

Why can't Tin-Free Steel be welded?

TFS has a stable chromium oxide layer on its surface. While this chromium oxide layer is very effective for paint adhesion and corrosion resistance (after coating), it interferes with the electrical current and heat transfer required for successful welding. Therefore, TFS components are typically joined using adhesives (gluing) or mechanical methods (such as two-piece canning).

Is tinplate safe for direct contact with food?

Yes, absolutely. Tinplate is one of the most trusted materials for food packaging worldwide. The inner tin coating acts as a non-toxic, protective barrier that prevents the steel from reacting with the food contents, preserving flavor and extending shelf life. It fully complies with international food safety standards.

Are both tinplate and TFS environmentally friendly?

Yes. Both materials are steel-based, making them 100% recyclable without any loss of quality. Steel is one of the most recycled materials on the planet. Choosing either tinplate or TFS is an environmentally responsible choice for packaging.

Why is Tin-Free Steel (TFS) considered more economical?

The cost difference comes down to the raw materials. The metallic chromium used to coat Tin-Free Steel is significantly less expensive than the pure tin used for tinplate. This makes TFS a highly cost-effective alternative for suitable applications like can ends and bottle caps.

Can you print high-quality graphics on both materials?

Yes, both materials can be printed on with excellent results. However, Tin-Free Steel (TFS) has superior adhesion to lacquers, inks, and paints. If your product requires intricate, multi-colored, or high-fidelity decorative finishes, TFS is often the preferred substrate.

Is Tinplate or Electrolytic Tin-Free Steel better for food packaging?

Tinplate is generally preferred for food packaging because of its excellent corrosion resistance, solderability, and food-safe properties. The tin coating protects contents from contamination, making it ideal for canned foods, beverage cans, and edible oil containers. Electrolytic tin-free steel (TFS) is often used for non-food applications or where additional internal coatings are applied.

Conclusion

Understanding the differences between tinplate and electrolytic tin-free steel is crucial when selecting the right material for your packaging needs. Whether you’re in the food industry or manufacturing general-purpose containers, Huaxiao Metal is here to provide expert guidance and reliable supply solutions.