AISI 1045 Steel Suppliers – Huaxiao Metal

1045 carbon steel is a medium carbon steel grade known for its excellent strength, toughness, and wear resistance. It is widely used in industrial applications such as shafts, gears, bolts, and forged parts.

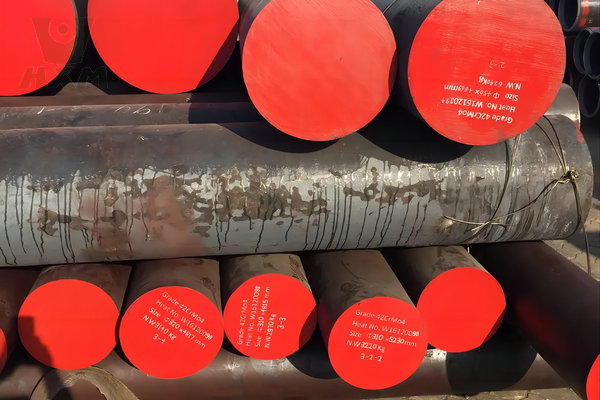

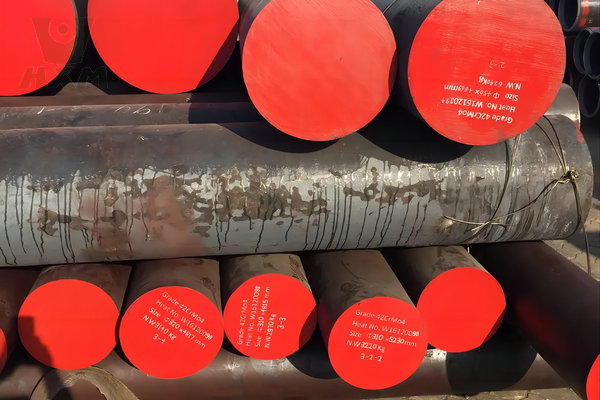

As reliable 1045 steel suppliers, Huaxiao Metal provides a wide range of 1045 carbon steel plates, coils, and bars in various sizes and specifications to meet global customer needs.

Looking for high-quality 1045 Carbon Steel Plates, Coils, Bars, and more? As a leading 1045 steel supplier and manufacturer, Huaxiao Metal offers competitive prices and global delivery. Contact us for 1045 steel stock and quotes today.

1045 Carbon Steel Available Products

- Round Bar

- Flat Bar

- Square Bar

- Hexagon Bar

- Plate

- Strip

We offer 1045 steel plates, tubes, and bars in different sizes in stock. We can also provide custom cutting, heat treatment, and surface treatment services according to customer needs.

Please send us specific inquiry details, we will quote for you within 24 hours!

Looking Forward to Becoming One of Your 1045 Steel Suppliers

Table of Contents

What is 1045 Steel?

AISI 1045 steel is a medium carbon steel commonly used in various industrial applications due to its excellent balance of strength, toughness, and wear resistance. The number “1045” represents its carbon content, indicating that it contains approximately 0.45% carbon by weight. This amount of carbon makes it a medium carbon steel, falling within the range of 0.30% to 0.60% carbon.

1045 Carbon Steel Data Sheet

1045 Carbon Steel Chemical Composition

Below is the chemical composition of 1045 grade steel presented in a table format:

| Element | Chemical Composition (%) |

|---|---|

| Carbon | 0.42 – 0.50 |

| Manganese | 0.60 – 0.90 |

| Phosphorus | 0.040 (max) |

| Sulfur | 0.050 (max) |

| Silicon | 0.15 – 0.35 |

1045 Carbon Steel Physical Properties

Here is a table showcasing the physical properties of 1045 carbon steel:

| Property | Value |

|---|---|

| Density | 7.87 g/cm³ (0.284 lb/in³) |

| Melting Point | 1480°C (2700°F) |

| Specific Heat | 0.49 J/g°C (0.117 BTU/lb°F) |

| Thermal Conductivity | 49.8 W/m°C (346 BTU-in/hr-ft²-°F) |

| Electrical Conductivity | 6.62% IACS (International Annealed Copper Standard) |

Looking Forward to Becoming One of Your 1045 Steel Suppliers

1045 Carbon Steel Mechanical Properties

The following table outlines the mechanical properties of AISI 1045 carbon steel.

| Tensile strength (psi) | 115,000 – 125,000 |

| Yield strength (psi) | 105,000 – 115,000 |

| Elongation in 2” (%) | 10 – 15 |

| Reduction of area (%) | 30 – 40 |

| Brinell Hardness (BHN) | 230 – 260 |

Looking Forward to Becoming One of Your 1045 Steel Suppliers

Equivalents of 1045 Carbon Steel

| Standard | Grade Equivalent |

|---|---|

| ASTM A29 | 1045 |

| ASTM A108 | 1045 |

| AISI | 1045 |

| SAE J403 | 1045 |

| EN 1.0503 (C45) | C45, 1.0503 |

| JIS G4051 | S45C |

| DIN 1.1191 | C45E (1.1191) |

| ISO 683-1 | C45E4 (1.1191) |

| GB/T 699 | 45 |

Looking Forward to Becoming One of Your 1045 Steel Suppliers

Advantages of 1045 Carbon Steel

1045 carbon steel offers several advantages, which contribute to its popularity and wide range of applications. Some of the key advantages include:

High Strength: 1045 steel has good tensile strength and yield strength, making it suitable for applications that require sturdy and durable components.

Wear Resistance: The medium carbon content and proper heat treatment allow 1045 steel to exhibit excellent wear resistance, reducing surface wear and extending the life of components.

Machinability: This steel grade has good machinability, making it easy to cut, machine, and fabricate into various shapes and components. It simplifies the manufacturing process and enhances productivity.

Versatility: 1045 steel is highly versatile and finds application in a wide range of industries, including automotive, machinery, construction, and manufacturing, due to its balanced combination of properties.

Cost-Effectiveness: Compared to some high-alloy steels, 1045 carbon steel is relatively more affordable, making it an economical choice for many applications without compromising on performance.

Weldability: When properly welded, 1045 steel exhibits satisfactory weldability, allowing it to be used in structures and components that require welding.

Heat Treatability: 1045 steel responds well to heat treatment, such as quenching and tempering, enabling the material to be tailored to specific mechanical properties for desired applications.

Consistency: It is a standardized steel grade, and its composition is well-defined across various international standards, ensuring consistent properties and reliable performance.

Ease of Availability: 1045 carbon steel is widely available and supplied by various manufacturers and distributors, making it easy to source for different projects and applications.

Due to its combination of strength, wear resistance, machinability, and cost-effectiveness, 1045 carbon steel remains a popular choice for a variety of industrial applications that require reliable and robust materials.

Looking Forward to Becoming One of Your 1045 Steel Suppliers

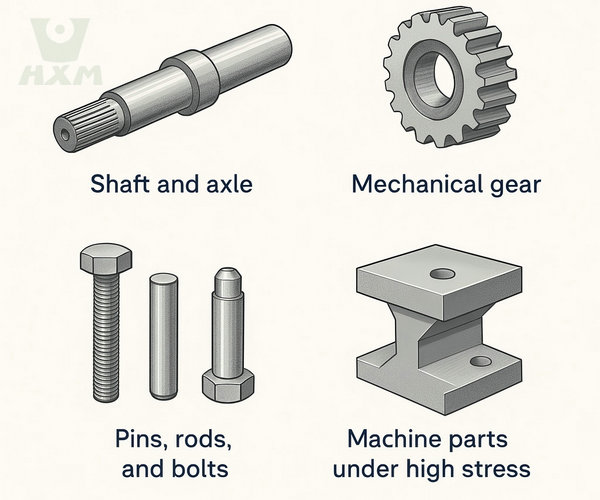

Applications of 1045 Carbon Steel

Here is a list of some common applications of 1045 carbon steel:

1. Shafts and Axles: 1045 steel’s high strength and wear resistance make it suitable for use in shafts and axles in various industrial machinery and automotive applications.

2. Gears and Sprockets: Its excellent machinability and toughness make 1045 steel a preferred choice for manufacturing gears and sprockets in power transmission systems.

3. Bolts, Nuts, and Fasteners: The combination of strength and cost-effectiveness makes 1045 steel an ideal material for producing various types of fasteners.

4. Hydraulic Components: The wear-resistant properties of 1045 steel are beneficial for manufacturing hydraulic components such as pistons and cylinders.

5. Machine Parts: Many machine parts, including spindles, couplings, and tool holders, are made from 1045 steel due to its versatility and machinability.

6. Bushings and Bearings: The wear resistance and strength of 1045 steel make it suitable for bushings and bearings in heavy machinery and equipment.

7. Crankshafts: In automotive and engine applications, 1045 steel is commonly used for crankshafts due to its durability and fatigue resistance.

8. Construction Equipment: Components in construction equipment, such as excavator arms and buckets, benefit from the toughness and strength of 1045 steel.

9. Hand Tools: Some hand tools, like hammers, chisels, and wrenches, are often made from 1045 steel due to its ability to withstand heavy use.

10. Agricultural Equipment: Various parts in agricultural machinery, such as plow blades and harrow tines, are fabricated using 1045 steel for its wear resistance.

11. Industrial Knives and Cutting Tools: The hardness and machinability of 1045 steel are advantageous for producing knives and cutting tools used in manufacturing processes.

12. Structural Components: In some applications, 1045 steel is utilized for constructing structural components that require moderate strength and toughness.

13. Oil and Gas Industry: Certain components in the oil and gas industry, such as pump shafts and valves, are made from 1045 steel due to its resistance to wear and corrosion.

Please note that this list is not exhaustive, and 1045 carbon steel finds use in various other applications where a combination of strength, wear resistance, and cost-effectiveness is essential.

Looking Forward to Becoming One of Your 1045 Steel Suppliers

Why choose Huaxiao Metal 1045 Steel Suppliers?

Huaxiao Metal is one of the outstanding 1045 steel suppliers in China. Here are some reasons why people choose Huaxiao as one of their suppliers:

Quality Assurance: A reputable supplier like Huaxiao Metal would ensure that their 1045 steel meets the required quality standards and specifications. They would have stringent quality control processes in place to deliver consistent and reliable products.

Wide Range of Products: A good supplier should offer a variety of 1045 steel products, such as sheets, plates, bars, and tubes, to cater to different customer needs and applications.

Competitive Pricing: Choosing a supplier with competitive pricing can help keep production costs down and improve overall profitability.

Prompt Delivery: Timely delivery of materials is crucial for manufacturing processes and projects, so a reliable supplier should have efficient logistics to ensure on-time delivery.

Technical Support: A reputable supplier would have a team of experts who can provide technical support and assistance, helping customers choose the right material and meet their specific requirements.

Customization Options: The ability to offer custom sizes, shapes, and processing services can be advantageous for customers who have unique specifications.

Industry Experience: A supplier with considerable experience in the steel industry is more likely to understand market trends, have established relationships with mills, and possess the expertise to provide valuable advice.

Reputation and Reviews: Checking customer reviews and the supplier’s reputation in the industry can give insights into their reliability and customer satisfaction.

Compliance and Certifications: Ensure that the supplier adheres to relevant industry standards and holds necessary certifications for quality assurance.

Customer Service: Excellent customer service is vital for a smooth buying experience. A good supplier should be responsive to inquiries and provide exceptional customer support.

Before selecting any steel supplier, it’s essential to conduct thorough research, compare multiple options, and assess their capabilities to ensure you partner with a trustworthy and dependable company.

We are proud to serve a variety of industries and we will work with you to find the right material for your job requirements. For more information, or to learn more about 1045 carbon steel, contact us today or request the 1045 steel price.

Looking Forward to Becoming One of Your 1045 Steel Suppliers

1045 Carbon Steel Related Requestions

1045 carbon steel is relatively strong with a tensile strength of about 570 MPa (82,700 psi) and a yield strength of around 330 MPa (47,900 psi).

To harden 1045 steel, it can be heated to a temperature of around 820-870°C (1508-1598°F) and then quenched in oil or water to rapidly cool it. This process is known as quenching and tempering, which imparts increased hardness and strength to the steel.

Yes, 1045 carbon steel is considered good due to its combination of strength, wear resistance, machinability, and cost-effectiveness. It is widely used in various industrial applications and is a popular choice for many engineering components and machinery parts.

Yes, 1045 carbon steel is susceptible to rusting if not properly protected. It contains iron, and like all carbon steels, it will corrode when exposed to moisture and oxygen, leading to the formation of rust. Proper maintenance and surface protection, such as coatings or platings, are essential to prevent rusting in 1045 carbon steel.

To heat treat 1045 steel, follow these simple steps:

Normalize: Heat the steel to around 870-900°C (1598-1652°F) and hold it at that temperature for a period based on the thickness of the material (about 1 hour per inch). Then, allow it to cool in still air.

Harden: Reheat the normalized steel to 820-870°C (1508-1598°F) and quench it in oil or water to rapidly cool it and achieve hardness.

Temper: Reheat the hardened steel to a temperature between 400-600°C (752-1112°F) and hold it for a specific time based on desired hardness. Then, allow it to cool in still air.

These steps are a general guide, and specific heat treatment processes may vary depending on the desired mechanical properties and the final application of the 1045 steel. Always follow appropriate safety guidelines and consult professional heat treatment experts when dealing with steel heat treatment.

To weld 1045 carbon steel, follow these simple guidelines:

Preparation: Clean the welding area to remove any dirt, oil, or contaminants that could affect the weld quality.

Select Welding Method: 1045 steel can be welded using various methods, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and stick welding. Choose the appropriate method based on the project requirements and your welding skills.

Preheat: Preheat the 1045 steel to reduce the risk of cracking during welding. The preheat temperature should typically be around 200-300°C (392-572°F).

Use Low-Hydrogen Electrodes: When using stick welding, use low-hydrogen electrodes (such as E7018) to minimize the risk of hydrogen-induced cracking.

Welding Techniques: Employ proper welding techniques and maintain a consistent arc to achieve strong and clean welds.

Post-Weld Heat Treatment: Depending on the application and desired properties, post-weld heat treatment may be necessary to relieve residual stresses and improve toughness.

Test Welds: Test the welds for quality and integrity to ensure they meet the required standards.

Always follow welding safety practices, and if you’re not experienced in welding, consider consulting a professional welder to ensure proper welding of 1045 carbon steel.

Contact Us For China 1045 Steel Prices

Get a quick quote today from a trusted 1045 steel supplier – Huaxiao Metal!

Contact us now for a quick quote or stock availability. Our experienced team will respond within 24 hours.

Huaxiao Metal Products

As a global steel supplier and manufacturer, Huaxiao offers a wide range of steel products for all your needs. Explore some of our most popular steel products.

Stainless Steel

Stainless Steel Sheet

Stainless Steel Coil

Stainless Steel Strip

Stainless Steel Foil

Stainless Steel Wire

Stainless Steel Bar

Stainless Steel Tube

Decorative Stainless Steel

Carbon Steel

Carbon Steel Wire

Carbon Steel Bar

Carbon Steel Tube

Coated Carbon Steel

Aluminum Metal

Aluminum Sheet

Aluminum Coil

Aluminum Strip

Aluminum Foil

Aluminum Wire

Aluminum Bar

Aluminum Tube