PCB Selection and Use of Copper Clad Laminate Features

The surface and core materials of the substrate used in composite-based printed circuit boards are composed of different reinforcing materials. The mechanical properties and manufacturing costs of composite-based copper clad laminates are between paper-based copper clad laminates and epoxy glass fiber cloth copper-clad laminates. The composite-based copper clad laminate substrates are mainly CEM (Composite Epoxy […]

Explosive Bonding VS Hot Bonding VS Cold Bonding

Explosive Bonding, Hot Bonding and Cold Bonding are three different metal bonding technologies, each with its own unique process principles, advantages and application scenarios. The following are the main differences between them: Clad Steel Process Principle Explosive Bonding Principle: Use the high-pressure shock wave generated by the explosion to press two or more metal materials […]

Steel Company News

1. Xiamen Xiangyu Co., Ltd.’s Indicative Announcement on the Controlling Shareholder’s Proposed Transfer of Jiangsu Delong’s Debts and Related Transactions On July 29, Xiamen Xiangyu Co., Ltd. issued an indicative announcement on the controlling shareholder’s proposed transfer of Jiangsu Delong’s debts and related transactions: Xiamen Xiangyu Group Co., Ltd. (hereinafter referred to as “Xiangyu Group”) […]

Brazil Launches Investigation into China Non-Oriented Silicon Steel

Brazil Launches AD Sunset Review Investigation on China Non-Oriented Silicon Steel On July 12, 2024, the Foreign Trade Secretariat of the Ministry of Development, Industry, Trade and Services of Brazil (Ministério do Desenvolvimento, Indústria, Comércio e Serviços/Secretaria de Comércio Exterior) issued Announcement No. 33 of 2024, in response to the application submitted by Aperam Inox […]

What is 20Cr2Ni4 Material?

20Cr2Ni4 is a low alloy carburizing steel widely used in the manufacture of mechanical parts that require high strength and wear resistance. This article will introduce the chemical composition, performance characteristics, main uses, and heat treatment process of 20Cr2Ni4 in detail to help readers fully understand this material. Carbon Steel 20Cr2Ni4 Material Data Sheet Chemical […]

What Steel Has High Hardness and Good Toughness?

This question can be roughly divided into three situations to answer: First, the hardness HRC of mold steel LG with good toughness is between 50-58. The hardness of LG mold steel is HRC56-58, and its toughness is 8-9 times that of DC53. The ability of steel to resist fracture under impact is called toughness. Simple […]

The Characteristics of the Welding Process of High Carbon Steel

The Characteristics of The Welding Process of High Carbon steel Preheating and post-heat treatment: Preheating and post-heat treatment are usually required to reduce the tendency of welding cracks. Preheating temperature: Generally between 150°C and 350°C, depending on the type of steel and thickness. Post-heat treatment: Slow cooling after welding and tempering treatment to reduce welding […]

What Steel Is EM2?

What Steel Is EM2? EM2 high-speed steel is a general-purpose tool steel widely used in rolling mills and other fields. Its chemical composition includes carbon, chromium, molybdenum, tungsten, vanadium, and other elements, and the content of these elements has an important influence on its performance. EM2 is a traditional Swedish high-speed tool steel with high […]

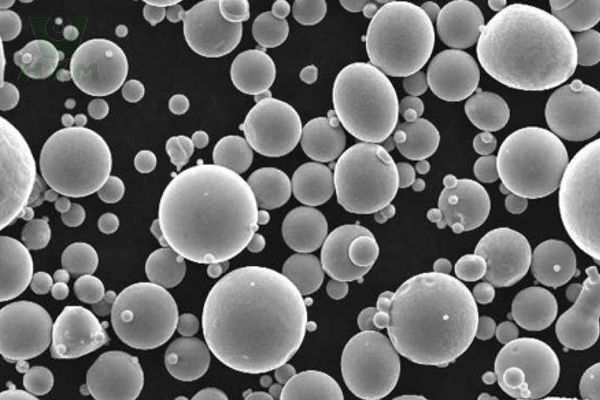

What Is Powder Steel?

Powder steel powder metallurgy is a metallurgical method using metal powder as raw material. It is a special process that uses a certain amount of metal powder to synthesize, mix, sinter, and other processes to smelt a new type of metal material that can be used to manufacture tools and accessories. Powder forging refers to […]

Carbon Structural Steel Grades

Carbon Structural Steel Grades Carbon structural steel can be divided into five grades: Q19, Q21, Q23, Q25, Q5, and Q27, with a carbon content range of 0.6-38%. Each grade is divided into several grades according to the different content of harmful impurities such as sulfur and phosphorus. The representation methods of AISI and SAE (American […]