Welcome to the definitive 1045 steel buyer’s guide. If you’re a procurement manager, engineer, or project leader, you know that sourcing the right industrial materials is critical for success. 1045 steel is one of the most versatile and widely used medium-tensile steels, prized for its excellent combination of strength, wear resistance, and toughness. But sourcing the right 1045 steel for your project can be a complex task. From navigating technical specifications to verifying quality and choosing a trustworthy supplier, the process is filled with potential pitfalls.

This is where many projects face delays and budget overruns—from receiving materials that don’t meet spec to dealing with unreliable vendors.

This guide is designed for procurement managers, engineers, and project leaders. We’ll provide a clear, step-by-step framework to help you source high-quality 1045 steel with confidence, ensuring you get the best possible material and value for your investment.

Defining Your 1045 Steel Requirements

The first step in any effective purchasing process is defining exactly what you need. Vague requests lead to inaccurate quotes. Use this checklist as part of your 1045 steel buyer’s guide to build your requirements. Here’s what to specify:

Form Factor

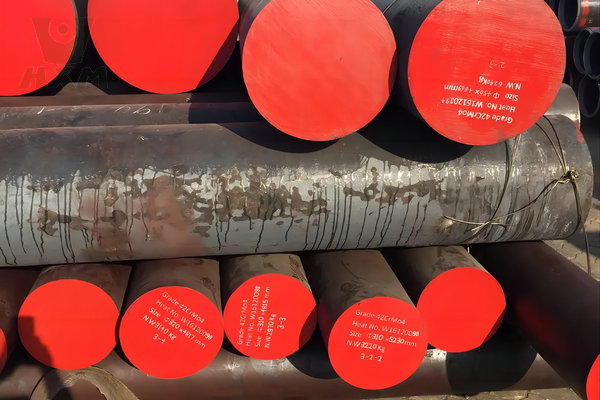

What shape and form do you need? 1045 steel is commonly available as:

Plate: Ideal for structural components and base plates.

Round Bar: Used for shafts, axles, bolts, and gears.

Sheet: Thinner than a plate, used for various fabricating purposes.

Custom-Cut Pieces: Sourcing from a supplier who offers precision cutting can save you significant time and downstream processing costs.

Critical Specifications

Dimensions & Tolerances: Clearly state the required thickness, width, length, or diameter. Crucially, also specify the dimensional tolerances your project can accept. Tighter tolerances may increase costs but are essential for precision applications.

Heat Treatment Condition: The “as-delivered” condition of the steel dramatically affects its properties and cost. Common conditions for 1045 steel include:

- As-Rolled: The most common and economical condition.

- Annealed: Softer and easier to machine.

- Normalized: Creates a more uniform and fine-grained structure.

- Quenched & Tempered (Q&T): Significantly increases hardness and strength.

Surface Finish: Do you need a standard black finish, or does your application require a rough-turned or polished surface?

Pro Tip: Not sure of the exact technical specifications needed for your application? An experienced supplier can help. Huaxiao Metal’s technical team is ready to assist you in determining the perfect requirements for your project.

How to Verify 1045 Steel Quality?

Quality cannot be compromised. Here’s how to ensure the 1045 steel you receive meets international standards and your project needs.

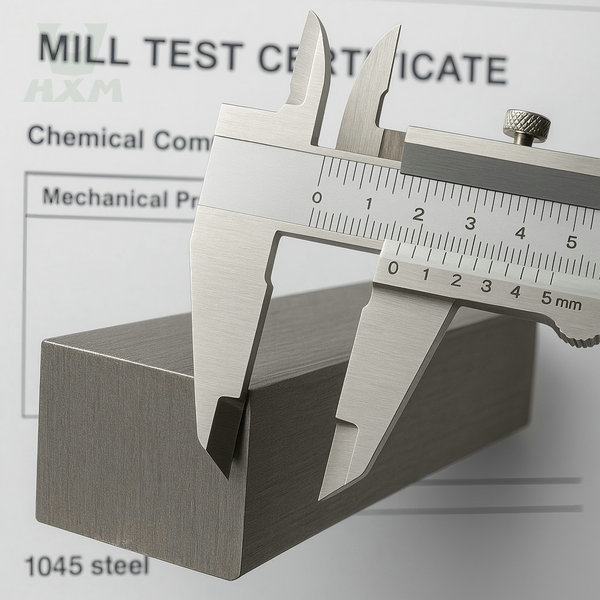

The Mill Test Certificate (MTC)

This is the single most important document for quality assurance. An MTC (also known as a material test report) is the steel’s “birth certificate.” Always insist on one.

Key information to check on the MTC:

Chemical Composition: Verify that elements like Carbon (C), Manganese (Mn), Phosphorus (P), and Sulfur (S) are within the specified ranges for AISI 1045 steel.

Mechanical Properties: Check the reported Tensile Strength, Yield Strength, and Elongation to ensure they meet your requirements.

At Huaxiao Metal, we provide a comprehensive Mill Test Certificate with every shipment, guaranteeing full traceability and compliance with industry standards.

Visual Inspection

Upon delivery, perform a visual check for any obvious defects like:

Surface cracks or deep scratches

Pitting or excessive rust

Lamination (layers separating)

Choosing a Reliable 1045 Steel Supplier

Your supplier is more than just a vendor; they are a partner in your project’s success. Here are the key attributes to look for:

Inventory & Availability: A reliable supplier should have a substantial inventory of common 1045 steel sizes and forms. This ensures faster delivery times and reduces the risk of project delays.

- Our Advantage: At Huaxiao Metal, we maintain a vast inventory of 1045 steel plates and bars, ready for immediate dispatch to clients worldwide.

Processing Capabilities: Can the supplier provide value-added services? In-house processing like precision cutting, drilling, and machining saves you logistical headaches and ensures the material is ready for your production line.

- Our Advantage: We offer a full suite of processing services, including cut-to-size, to deliver 1045 steel that perfectly matches your drawings.

Logistics & Global Shipping Experience: Especially for international buyers, choosing a supplier with proven experience in global logistics is critical. They should be able to handle packaging, documentation, and shipping to ensure your material arrives safely and on time.

- Our Advantage: Huaxiao Metal has years of experience exporting steel products globally. We manage the entire logistics process, from robust packaging to seamless customs clearance.

Experience & Expertise: Look for a supplier with a long history and a team that understands the technical nuances of steel. An expert partner can offer valuable advice and help you avoid costly mistakes.

FAQ for Buying 1045 Steel

Can I buy a small quantity of 1045 steel?

Yes, many modern suppliers and stockists, including Huaxiao Metal, can accommodate smaller orders or cut-to-size pieces from larger plates or bars. Always inquire about minimum order quantities (MOQ) when you request a quote.

How does heat treatment affect my purchase?

Heat treatment like Quenching & Tempering (Q&T) increases the hardness and strength of 1045 steel, but also the cost and lead time. The “as-rolled” condition is the most economical starting point. This guide advises discussing your performance needs with your supplier to choose the most cost-effective treatment.

What is the most important factor when buying 1045 steel?

While price is a factor, the most important thing is ensuring the material’s quality and specifications, confirmed by a valid Mill Test Certificate (MTC). Buying a cheaper, out-of-spec product is far more costly in the long run.

In Conclusion: 1045 Steel Buyer's Guide

Buying 1045 steel doesn’t have to be difficult. By following a structured approach—identifying your needs, verifying quality, and choosing a professional partner—you can obtain the right material efficiently and cost-effectively.

Huaxiao Metal is more than just a supplier; we are your partner in fabrication and construction. We are committed to providing high-quality 1045 steel and providing the support and reliability you need to ensure your project is completed successfully.