When choosing a mild steel for cold forming, stamping or automotive parts, 1008 vs 1010 steels are two of the most commonly used grades. But how do you choose the right grade for your application? In this guide, we’ll compare 1008 and 1010 steels based on chemical composition, mechanical properties, formability, cost and industrial uses.

Looking for reliable 1008 or 1010 steel suppliers? Contact Huaxiao Metal for a quote today!

What Is 1008 Steel?

1008 Steel

1008 Steel – Premium Low Carbon Steel from Huaxiao Metal 1008 steel is a common low-carbon steel with excellent weldability and formability, making it ideal

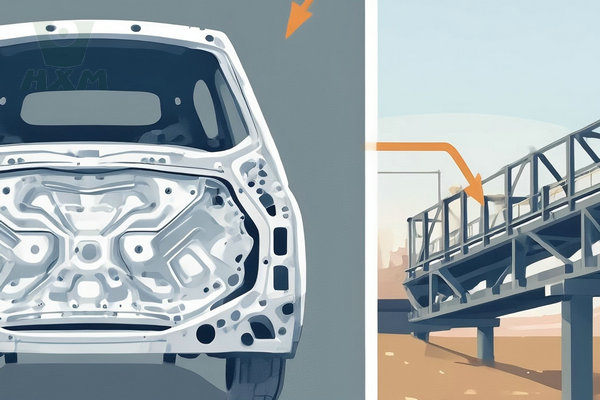

1008 steel is a low-carbon mild steel known for its excellent formability and weldability. With a typical carbon content of 0.08%, it is ideal for deep drawing applications such as automotive panels, home appliances, and wire.

If you are looking for a metal material with high ductility and smooth surface finish at an affordable price, 1008 steel is worth your consideration.

What Is 1010 Steel?

1010 steel is a low carbon steel with a carbon content of approximately 0.10%. It strikes a balance between strength and formability, making it suitable for structural parts, automotive components, and machinery manufacturing.

Compared to 1008 steel, 1010 steel is slightly stronger while still maintaining good formability.

Need to purchase 1010 steel for your manufacturing needs? Contact us today for pricing.

1010 Steel

1010 Steel – Your Trusted Supplier for Sheet, Plate, Coil & Bar 1010 Carbon Steel is a widely used low-carbon steel known for its excellent

1008 vs 1010 Steel: Key Differences and Applications

1008 vs 1010 Steel: Chemical Composition Comparison

| Element | SAE 1008 | SAE 1010 |

|---|---|---|

| C | ≤ 0.10% | 0.08 – 0.13% |

| Mn | 0.30 – 0.50% | 0.30 – 0.60% |

| P | ≤ 0.04% | ≤ 0.04% |

| S | ≤ 0.05% | ≤ 0.05% |

Key Insight: 1008 steel contains slightly lower carbon, which improves ductility and makes it better for deep drawing. In contrast, 1010 offers higher strength, making it more suitable for light structural components.

Need help choosing between 1008 and 1010 carbon steel? Contact Huaxiao Metal for material selection advice or a quick quote.

1008 vs 1010 Steel: Mechanical Properties Comparison

| Property | 1008 Steel | 1010 Steel |

|---|---|---|

| Tensile Strength | ~300 MPa | ~365 MPa |

| Yield Strength | ~170 MPa | ~210 MPa |

| Elongation | ~30% | ~25% |

| Hardness | ~70 HRB | ~80 HRB |

Forming or stamping complex parts? 1008 might be your best choice. Ask Huaxiao Metal for technical support or data sheets.

Applications of 1008 and 1010 Steel

| Application | 1008 Steel | 1010 Steel |

|---|---|---|

| Deep drawing | ✅ | 🔘 |

| Automotive brackets | ✅ | ✅ |

| Light structural parts | 🔘 | ✅ |

| Wire products | ✅ | ✅ |

| Fasteners | ✅ | ✅ |

| Appliance components | ✅ | ✅ |

1008 carbon steel is the preferred choice for cold heading, deep-drawn parts, and soft steel wire, whereas 1010 carbon steel is favored in light framing, tubing, and general-purpose structural parts.

Exporting automotive or industrial components? Huaxiao Metal offers both 1008 and 1010 carbon steel with international certifications and quick delivery. Request a sample today!

Price & Cost Consideration

In most markets, 1008 and 1010 steel prices are very close, with 1010 being marginally more expensive due to slightly higher carbon content and strength. However, the choice should depend more on performance requirements than just price.

Want to compare today’s prices for 1008 vs 1010 steel? Huaxiao Metal offers competitive mill-direct pricing—get your quotation now.

1008 vs 1010 Steel: Weldability & Machinability

Both 1008 and 1010 steels are known for excellent weldability, with minor differences in machinability:

1008: Easier to machine due to lower hardness.

1010: Slightly harder, better suited for rigid components.

Not sure which carbon steel grade suits your needs? Our engineers are here to help — send us your specs!

Which One Should You Choose? 1008 vs 1010 Steel

| If You Need… | Choose |

|---|---|

| High ductility and formability | 1008 |

| Higher strength and rigidity | 1010 |

| Cold heading or deep drawing | 1008 |

| General-purpose applications | 1010 |

Huaxiao Metal provides 1008 and 1010 carbon steel coils, plates, strips, and custom sizes to customers around the world. Whether you are purchasing for automotive manufacturing, metal stamping or structural applications, our team is ready to meet your procurement needs.

Looking for a trusted carbon steel material supplier? Contact Huaxiao Metal today to learn about availability, minimum order quantity, and shipping options.

Why Choose Huaxiao Metal as Your Carbon Steel Supplier?

At Huaxiao Metal, we stock carbon steel products in various grades and specifications. With competitive carbon steel prices, strict quality control, and fast global shipping, we help our customers find the best steel solution.

✅ Large Inventory

✅ Custom Sizing

✅ Export Experience

✅ Reliable Quality

In Conclusion:

Choosing between 1008 and 1010 carbon steel depends on your specific project needs – formability vs. strength, ductility vs. stiffness. Both grades are widely used and economical across a wide range of industries.

Still unsure which carbon steel grade is right for your project? Contact our technical team directly for fast support, expert guidance and more.