Precipitation-hardening stainless steel, often referred to as PH stainless steel, combines the corrosion resistance of stainless steel with enhanced mechanical strength through a heat treatment process. This makes it an ideal material for high-performance applications across aerospace, petrochemical, medical, and marine industries.

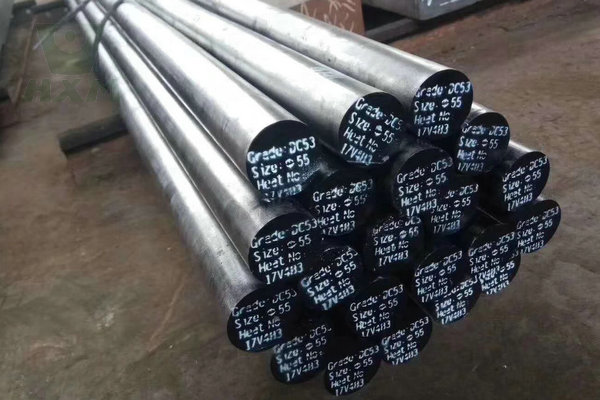

At Huaxiao Metal, we provide a wide range of precipitation-hardening stainless steel alloys, including popular grades such as 17-4PH, 15-5PH, and 13-8Mo, available in various forms like bars, plates, and coils. Whether you’re sourcing for precision components or structural applications, our PH stainless steels offer reliable performance and competitive pricing.

What is Precipitation-Hardening Stainless Steel?

Precipitation-hardening stainless steel is an iron-based alloy that strengthens through a precipitation heat treatment process. This involves solution treatment, quenching, and aging, which allows the formation of fine intermetallic particles that block dislocation motion, greatly increasing strength and hardness.

Key alloying elements include:

Copper (Cu): Enhances aging response

Aluminum (Al): Forms fine precipitates during aging

Niobium (Nb) or Titanium (Ti): Controls grain size and precipitation behavior

Chromium (Cr): Maintains corrosion resistance

Nickel (Ni): Stabilizes austenitic structure

Types of PH Stainless Steel Alloys

17-4PH (UNS S17400)

Best balance of strength, corrosion resistance, and price

Mechanical strength up to 1100 MPa (160 ksi)

Heat treatable at 480°C or 620°C for different property profiles

Applications: Aerospace fittings, marine shafts, nuclear components

15-5PH (UNS S15500)

Improved toughness over 17-4PH

Good weldability and corrosion resistance

Common in aerospace and chemical processing

13-8Mo (UNS S13800)

Superior toughness and fatigue strength

Excellent resistance to stress corrosion cracking

Ideal for aerospace and high-performance mechanical parts

The Heat Treatment Process of PH Stainless Steel

The typical hardening process includes:

Solution Annealing

Heating the alloy to a high temperature (around 1000–1050°C) to dissolve alloying elements into the matrix.

Quenching

Rapid cooling to trap alloying elements in solid solution.

Aging (Precipitation Treatment)

Reheating to a lower temperature (typically 480–620°C) to form fine precipitates.

Each grade has unique aging conditions, influencing the final hardness and strength. For example, 17-4PH aged at 482°C (H900 condition) achieves maximum strength but reduced toughness, whereas aging at 620°C (H1150) offers lower strength but better ductility and toughness.

Benefits of Precipitation-Hardening Stainless Steel

High yield strength and hardness after aging

Good corrosion resistance in most environments

Machinable and weldable in solution-annealed condition

Stable mechanical properties over time

Lower distortion during heat treatment than martensitic grades

Precipitation-hardening stainless steel alloys provide the best of both worlds: high mechanical strength and corrosion resistance. Whether you need 17-4PH or other grades, Huaxiao Metal is your trusted partner.

Contact us today to get the latest PH stainless steel prices, learn more about available stock, and inquire about custom orders!

Applications of PH Stainless Steel

Aerospace components

Injection molding tools

Valves and fasteners

Nuclear reactor parts

Oil and gas equipment

Surgical instruments

Huaxiao Metal – Your Reliable PH Stainless Steel Supplier

At Huaxiao Metal, we offer:

Comprehensive inventory of 17-4PH, 15-5PH, and more

Cut-to-size service for your specific needs

Competitive prices and international delivery

Technical support for material selection and heat treatment

Contact us now to consult PH stainless steel prices, check availability, or request a free quote.

FAQs about Precipitation-Hardening Stainless Steel

What’s the difference between 17-4PH and 15-5PH stainless steel?

While both are martensitic PH stainless steels, 15-5PH offers better toughness and is more weldable, while 17-4PH has slightly higher hardness.

Can PH stainless steels be welded?

Yes, especially in the solution-annealed condition. Post-weld heat treatment is often required to restore properties.

Is precipitation-hardening stainless steel magnetic?

Most PH stainless steels are magnetic due to their martensitic structure after aging.

How does PH stainless steel compare to austenitic grades like 304 or 316?

PH steels offer much higher strength but slightly less corrosion resistance than 316.

| Property | 304 / 316 Stainless Steel | PH Stainless Steel (17-4PH, 15-5PH) |

|---|---|---|

| Strength | Moderate | Very High |

| Corrosion Resistance | Excellent (316 > 304) | Good (better than martensitic) |

| Magnetism | Non-magnetic | Magnetic after aging |

| Heat Treatable | Not hardenable by heat | Hardenable through aging |

| Applications | General-purpose | Aerospace, high-load environments |

What’s the Difference Between Annealed and Tempered Precipitation Hardening Stainless Steels?

Annealing and tempering are traditional heat treatment processes, while precipitation hardening is a strengthening method for specific stainless steels (such as 17-4PH). The main differences are as follows:

Annealing: used to soften metals and improve plasticity, often used before and after processing; the process is usually heated and then slowly cooled.

Tempering: often used in conjunction with quenching to reduce hardness and eliminate internal stress; heat preservation and cooling after heating.

Precipitation hardening: first dissolve strengthening elements (solid solution treatment), then heat at low temperature (aging), promote the precipitation of fine particles, and significantly improve strength and hardness.

Simply put: annealing and tempering are “relaxation” treatments, and precipitation hardening is a “strengthening” treatment.

What forms are available from Huaxiao Metal?

We supply PH stainless steel in bars, sheets, coils, and plates, customized to your specifications.