This is a question we are often asked: Does galvanized steel rust? The simple answer is: Yes, but it is designed to greatly slow the rusting process, providing decades of protection in most applications.

Galvanized steel is a common metal material that is widely used in various fields such as building structures, pipelines, and household appliances. Its core value lies in its excellent corrosion resistance. But this layer of protection is not permanent. However, whether galvanized steel will rust has always puzzled people.

In this article, we will delve into the scientific principles of galvanized steel rust prevention, explain under what circumstances it will rust (including the difference between “white rust” and “red rust”), and teach you how to choose and maintain it to maximize its service life etc.

What Exactly Is Galvanized Steel?

Imagine putting a strong “armor” on steel. That’s basically how galvanizing works. Galvanizing steel is a process that protects steel from corrosion (rust) by covering it with a protective coating of zinc.

This zinc “armor” is created in two main ways:

Hot-Dip Galvanizing: This is the most common and most durable method. The steel is completely immersed in molten zinc to form a metallurgically bonded, very thick alloy layer.

Electro-Galvanizing: Zinc ions are deposited onto the surface of the steel by passing an electric current through an electrolyte. This method produces a thinner, more uniform coating with a smoother appearance, but is not as corrosion resistant as hot-dip galvanizing.

As a leading metal material supplier, Huaxiao Metal offers a comprehensive range of galvanized steel products to meet your various needs.

- Hot-Dipped Galvanized Sheets/Coils (GI): Suitable for building roofs, wall panels, HVAC ducts, etc.

- Electro-galvanized Sheets/Coils (EG): Suitable for home appliance housings, automotive inner panels, etc. that require a smooth surface.

- Galvanized Pipes/Profiles: Widely used in fencing, scaffolding, and structural support.

Ready to purchase high-quality galvanized steel for your project?

Does Galvanized Steel Rust?

Yes, galvanized steel rust, but it is more resistant to rust compared to untreated steel. Galvanized steel is generally less susceptible to rust because it has been galvanized, which is a coating of zinc on the surface of the steel. This layer of zinc acts as a protective barrier, preventing the steel from coming into contact with moisture and oxygen, two of the main factors that cause rust. The zinc layer on galvanized steel resists corrosion in most everyday environments.

Factors that Rust and Corrode Galvanized Steel:

Although galvanized steel is relatively rust-resistant, it can still rust, depending on the following factors:

- Damage to the zinc layer: If the zinc layer on the surface of galvanized steel suffers scratches, dents, or other physical damage, the protective effect of the zinc layer will be weakened, causing the exposed steel to rust.

- Wear of the zinc coating: Over time, the zinc coating can wear away, especially in high-wear areas. This can leave galvanized steel susceptible to corrosion.

- Special environments: Galvanized steel may rust more easily in certain special environments, such as seawater containing salt or chlorine.

- High Temperature: The zinc layer of galvanized steel may be more susceptible to corrosion in high-temperature environments, especially when in contact with moisture.

There are two completely different types of “rust” on galvanized steel:

White Rust – Zinc “Rust”

What is it: White rust is a white, powdery, or pasty substance whose chemical composition is zinc hydroxide. It forms under certain conditions (such as stacked galvanized sheets in a damp, poorly ventilated environment).

Is it harmful? White rust is a sign of corrosion of the zinc layer, but it is not rust on the steel. Light white rust usually does not significantly affect the life of the zinc coating, but severe white rust will consume the zinc layer.

How to deal with it: It can be removed with a hard nylon brush and appropriate detergent. The galvanized products provided by Huaxiao Metal are usually passivated or oiled to minimize the formation of white rust during transportation and storage.

Red Rust – Steel “Rust”

What is it: This is what we usually call “rust,” and its chemical composition is iron oxide.

When does it appear: Only when the zinc of the galvanized layer is completely consumed, or when the coating is deeply scratched and the sacrificial protection is exhausted, will the steel inside begin to be exposed to the corrosive environment and form red rust.

What it means: Seeing red rust means that the life of the galvanized layer has come to an end, and the steel structure has begun to suffer.

How to Prevent Galvanized Steel from Rusting:

To prevent galvanized steel from rusting, you can take the following precautions:

- Regular Inspections: Regularly inspect the surface of galvanized steel to look for any breaks, scratches or damage to the zinc layer and repair them promptly.

- Prevent chemical exposure: Avoid exposing galvanized steel to chemicals that may cause corrosion of the zinc coating.

- Keep it Dry: Try to avoid exposing galvanized steel to prolonged moisture.

Key Factors Affecting the Life of Galvanized Steel

The life of the galvanized layer is not a fixed value; it is strongly affected by the following key factors:

| Environment Type | Corrosion Level | Estimated Lifespan of Hot-Dip Galvanizing (per ASTM A123) |

|---|---|---|

| Indoor (Dry Conditions) | Very Low | 100+ years |

| Rural Areas | Low | 60 – 100 years |

| Urban/Moderate City Areas | Moderate | 40 – 80 years |

| Coastal/Industrial Areas | High/Severe | 10 – 30 years |

Coating Thickness: This is the most important factor. The thicker the coating, the longer the life. Huaxiao Metal can provide products with different zinc coating thicknesses (such as Z100, Z180, Z275) according to your application environment.

Physical Damage: Cuts, drillings, and deep scratches will expose the steel base and accelerate the consumption of zinc.

Chemical Exposure: Long-term exposure to acids, strong bases, or other corrosive chemicals will drastically shorten its life.

Galvanized Steel vs. Stainless Steel vs. Aluminum

Choosing the right material for your project is crucial. Here is a quick comparison:

| Property | Galvanized Steel | Stainless Steel (Type 304) | Aluminum |

|---|---|---|---|

| Corrosion Resistance | Good to Excellent | Excellent | Excellent (oxidizes but forms a protective layer) |

| Cost | Low | High | Medium |

| Strength | Very High | Very High | Medium |

| Weight | Heavy | Heavy | Light |

| Best Suited For | Cost-sensitive structural applications, construction, agricultural fencing, and automotive parts | Food processing, medical equipment, marine environments, and architectural finishes | Aerospace, window frames, and applications requiring lightweight and corrosion resistance |

Conclusion: If your project requires high strength and excellent corrosion resistance, and budget is a key consideration, galvanized steel is often the unbeatable choice.

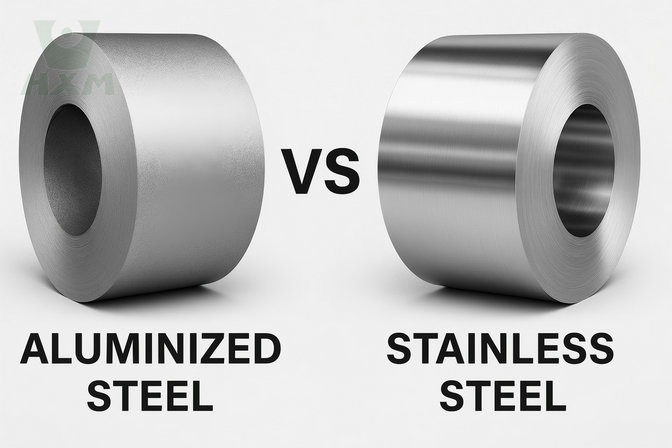

Aluminized Steel vs Stainless Steel: What’s the Difference?

Choosing the right material for your project is crucial—especially when it comes to choosing between aluminized steel vs stainless steel. Both materials excel in industrial,

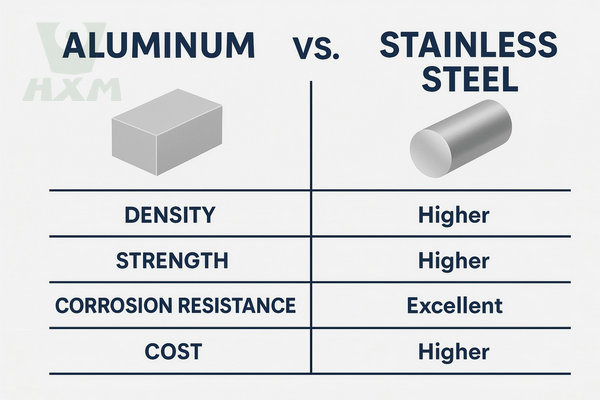

Galvanized Steel vs Aluminum: What’s the Difference?

When it comes to choosing materials for construction, manufacturing, or other applications, galvanized steel and aluminum are two prominent choices that each have their own

Aluminum Vs Stainless Steel

When it comes to choosing materials for various applications, aluminum vs stainless steel are two popular options with distinct characteristics. Both metals have unique properties

FAQ

Can you paint on galvanized steel?

Yes, but it requires the right surface preparation. Oil and impurities must be removed first, and a primer (etching primer) designed specifically for galvanized surfaces must be used, otherwise the paint will peel off easily.

How to remove white rust from galvanized steel?

For minor white rust, you can wipe it with a cloth dipped in white vinegar, then rinse it with clean water and dry it thoroughly. For more severe white rust, it may be necessary to use a mechanical method (such as a nylon brush) to gently brush it off.

Is galvanized steel safe for the human body or the environment?

It is completely safe in normal use. Zinc fumes are produced when welding or high-temperature cutting of galvanized steel, which requires good ventilation and professional protective measures. It is also a green material that is fully recyclable.

In Conclusion:

So, back to our original question: Does galvanized steel rust? The answer is yes, but only after its strong zinc armor has worn out after decades (or more) of faithful service.

By understanding how it works, what factors affect its longevity, and the right maintenance methods, you can ensure you get the most out of your investment. Galvanized steel remains one of the most reliable and cost-effective corrosion protection solutions on the market today.

Have questions about your project, or need a custom quote for a large volume purchase?

With decades of expertise, our team is ready to help.