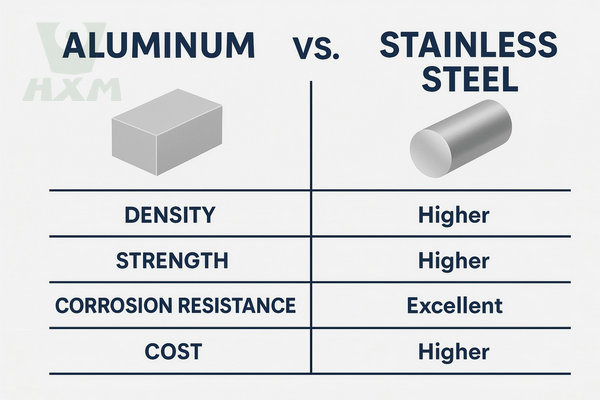

Quick Comparison: Aluminum vs Stainless Steel

| Property | Aluminum | Stainless Steel | Key Insight |

|---|---|---|---|

| Strength-to-Weight Ratio | Very High | Good | Aluminum offers superior structural strength at the same weight, ideal for lightweight applications. |

| Absolute Strength | Moderate | Very High | Stainless steel is significantly stronger and more impact-resistant when weight is not a factor. |

| Corrosion Resistance | Good | Excellent | Stainless steel (especially 316L) performs better in salt spray and harsh chemical environments. |

| Thermal/Electrical Conductivity | Excellent | Poor | Aluminum is an outstanding heat and electrical conductor; stainless steel is comparatively insulating. |

| Cost | Lower | Higher | Aluminum is generally cheaper, but prices vary by grade and market trends. |

| Workability | Excellent | Good | Aluminum is softer and easier to cut, bend, and form. |

| Weldability | Good | Excellent | Stainless steel is generally easier to weld, especially in structural applications. |

| Appearance | Matte silver | Bright or brushed | Both metals offer various surface treatments to meet aesthetic preferences. |

Aluminum Vs Stainless Steel: Composition and Properties

Aluminum:

Aluminum is a lightweight metal with a low density and excellent corrosion resistance. It is highly malleable and ductile, allowing it to be easily shaped into different forms. Despite its lightweight nature, aluminum has a good strength-to-weight ratio, making it suitable for applications where weight reduction is crucial.

Stainless Steel:

Stainless steel, on the other hand, is an alloy composed of iron, chromium, and other elements. It is known for its exceptional strength, durability, and resistance to corrosion and staining. Stainless steel comes in various grades, each with its unique properties, such as increased resistance to heat or improved mechanical strength.

Aluminum Vs Stainless Steel: Strength and Durability

Aluminum:

While aluminum is lightweight, it is not as strong as stainless steel. Its lower tensile strength makes it more prone to deformation or structural failure under heavy loads. However, aluminum alloys can be strengthened through processes like heat treatment or alloying with other metals.

Stainless Steel:

Stainless steel is significantly stronger and more durable than aluminum. It has higher tensile strength, allowing it to withstand heavy loads without deforming. This strength makes stainless steel suitable for applications that require robustness and resistance to wear and tear.

Aluminum Vs Stainless Steel: Corrosion Resistance

Aluminum:

Aluminum has excellent corrosion resistance due to its natural oxide layer, which forms when exposed to air. However, it is susceptible to certain types of corrosion, such as pitting corrosion in saline environments. To enhance its corrosion resistance, aluminum can be anodized or coated with protective layers.

Stainless Steel:

Stainless steel is renowned for its exceptional resistance to corrosion. The presence of chromium in stainless steel forms a passive oxide layer that protects the underlying metal from corrosion. This property makes stainless steel ideal for applications where exposure to moisture or corrosive substances is prevalent.

Aluminum Vs Stainless Steel: Application

Aluminum:

Stainless Steel:

how to tell the difference between aluminum and stainless steel?

To tell the difference between aluminum and stainless steel, you can consider the following characteristics:

Appearance:

Aluminum: Aluminum has a light silver or gray color and a slightly dull or matte finish. It often has a smoother surface texture compared to stainless steel.

Stainless Steel: Stainless steel has a brighter and shinier appearance than aluminum. It has a reflective surface with a polished or brushed finish. Stainless steel may have a slightly yellowish tint or a gray color, depending on the specific alloy.

Weight:

Aluminum: Aluminum is significantly lighter than stainless steel. If you have two objects of the same size, the one made of aluminum will feel much lighter when lifted.

Stainless Steel: Stainless steel is denser and heavier than aluminum. Objects made of stainless steel will feel more substantial and have a noticeable weight when compared to aluminum.

Magnetic Properties:

Aluminum: Aluminum is non-magnetic, which means it does not attract magnets. If a magnet does not stick to the metal, it is likely to be aluminum.

Stainless Steel: Most stainless steels are also non-magnetic, but there are some exceptions. Some stainless steel alloys have magnetic properties, which means a magnet may stick to the metal surface. If a magnet sticks, it could be stainless steel, but further testing may be needed to confirm.

Corrosion Resistance:

Aluminum: Aluminum has a natural oxide layer that forms when exposed to air, providing good corrosion resistance. However, it can still corrode in certain conditions, especially in saline environments or when in contact with acidic substances.

Stainless Steel: Stainless steel is highly resistant to corrosion due to the presence of chromium, which forms a protective oxide layer on the surface. Stainless steel can withstand exposure to moisture, chemicals, and corrosive environments better than aluminum.

Strength:

Aluminum: Aluminum is a relatively soft metal compared to stainless steel. It has lower tensile strength and is more prone to deformation or bending under heavy loads.

Stainless Steel: Stainless steel is much stronger and has higher tensile strength than aluminum. It can withstand greater loads and is more resistant to deformation or bending.

Conductivity:

Aluminum: Aluminum is an excellent conductor of heat and electricity. It is widely used in applications where thermal or electrical conductivity is essential, such as in electrical wires or heat sinks.

Stainless Steel: Stainless steel has lower thermal and electrical conductivity compared to aluminum. It is not as efficient in conducting heat or electricity.

Thermal Conductivity: heat sink or thermos?

This is an often-overlooked but crucial distinction.

Aluminum: Aluminum is an excellent conductor of heat and electricity. Its thermal conductivity makes it ideal for LED light housings, electronics heat sinks, computer CPU heat sinks, and heat exchangers.

Stainless steel: Stainless steel has a very poor thermal conductivity, making it an excellent insulator. This is why high-end cookware has multiple layers of material (often with an aluminum core) for even heat conduction, and stainless steel handles to prevent burns.

Decision point: Does your product need to dissipate heat quickly or maintain temperature?

By considering these factors, including appearance, weight, magnetic properties, corrosion resistance, strength, and conductivity, you can differentiate between aluminum and stainless steel.

How to Choose the Right Material for your Project? (Application Scenario Guide)

Combining theory with practice, here are some common application scenarios to help you make the final decision:

Scenario 1: Marine equipment, coastal building railings

- Recommendation: 316L stainless steel. Its excellent resistance to chloride corrosion is the only reliable choice.

Scenario 2: Drone frames, lightweight automotive parts, vehicles

- Recommendation: High-strength aluminum alloys such as 6061 or 7075. The ultimate strength-to-weight ratio is the core requirement here.

Scenario 3: Electronic equipment housing, LED lighting, heat sink

- Recommendation: Aluminum. Excellent heat dissipation performance can effectively extend the life of electronic components.

Scenario 4: Food processing equipment, kitchen utensils, medical devices

- Recommendation: 304 or 316L food-grade stainless steel. It is easy to clean, non-toxic, does not react with food, and meets hygiene standards.

Scene 5: Building curtain walls, interior decorative lines

- Recommendation: Both, depending on the design. Brushed stainless steel provides a modern industrial feel, while anodized aluminum provides a richer color selection and a light texture.

FAQ: Aluminum Vs Stainless Steel

For outdoor use, which is better, aluminum or stainless steel?

It depends on the specific environment. In general urban environments, both are fine. But in coastal or industrial areas with high salt content and high pollution, the durability of 316L stainless steel far exceeds that of aluminum.

Which is more expensive, aluminum or stainless steel, given the same strength requirements?

This is a common misconception. Although stainless steel is more expensive per kilogram, it is much stronger. In some applications, you may need a 3mm thick aluminum plate to achieve the strength of a 1mm thick stainless steel plate. In this case, the final cost of the two may be very close, considering the material usage. We need to calculate it based on your specific load requirements.

Our company's equipment is designed for processing steel. Can it be used directly to process aluminum?

Not entirely. Aluminum is softer and more sticky, and requires higher speeds and specially designed tools when cutting to prevent the material from melting and sticking to the tool. Welding aluminum requires an AC TIG welder and a special shielding gas, which is different from the DC process for welding steel. Forcing a mixture will result in poor processing quality and equipment damage.

If my project requires both strength and lightness, is there a compromise?

Yes. One option is to use a high-strength aluminum alloy (such as 7075). Another common engineering solution is to mix materials: use stainless steel as the core load-bearing frame and aluminum as the covering panels and secondary structure. We can provide cut-to-length processing services for both materials according to your design.

In conclusion

In conclusion, aluminum and stainless steel are two distinct metals with different properties and applications. Aluminum is lightweight and corrosion-resistant, while stainless steel is stronger, more durable, and highly resistant to corrosion. The choice between aluminum and stainless steel depends on the specific requirements of the application, considering factors such as weight, strength, and environmental conditions. Both metals have their unique advantages, and understanding their properties helps in selecting the appropriate material for a given project.