In industries where strength and corrosion resistance are both critical, clad stainless steel has become a game-changing solution. But what is clad stainless steel? How does it differ from traditional stainless or carbon steel? In this guide, we’ll explore what clad stainless steel is, how it’s made, its key benefits, and how to choose a reliable clad stainless steel manufacturer or supplier.

Looking for custom sizes or technical consultation? Contact Huaxiao Metal today for a quick response and a free quote.

What Is Clad Stainless Steel?

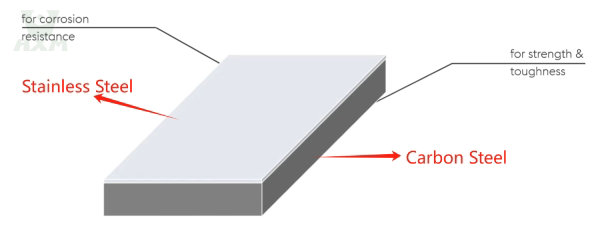

Clad stainless steel is a composite metal material made by combining a thin outer layer of stainless steel with a stronger, usually cheaper base material (such as carbon steel or alloy steel) through a cladding process. This fusion gives the material the corrosion resistance of stainless steel with the strength, machinability, and cost-effectiveness of the base material.

It is widely used in environments that require both durability and chemical resistance, such as pressure vessels, chemical storage tanks, and heat exchangers.

Serving over 50 countries. Shipping over 1000 tons of clad steel per year.

Need bulk clad stainless steel with guaranteed delivery times and competitive prices? Request a quote now – our sales team will respond within 24 hours.

Manufacturing Processes of Clad Stainless Steel

There are two widely used manufacturing methods to produce clad stainless steel:

1. Hot-Roll Bonding

Involves rolling two or more metals together at high temperatures and pressure.

Common for large-volume production.

Ensures high-strength metallurgical bonding.

2. Explosion Bonding

Uses a controlled explosion to instantly bond dissimilar metals.

Ideal for bonding corrosion-resistant alloys to tough structural bases.

Suitable for custom or specialty applications.

Explosive Bonding VS Hot Bonding VS Cold Bonding

Explosive Bonding, Hot Bonding and Cold Bonding are three different metal bonding technologies, each with its own unique process principles, advantages and application scenarios. The

Need help choosing the right cladding method? Our engineers at Huaxiao Metal provide free technical support based on your application and budget.

Send us your specifications now and we’ll provide you with a cladding process recommendation and quote within 24 hours.

Things To Note When Stainless Steel Cladding

While clad stainless steel offers cost and performance advantages, there are still several key factors to consider during material selection and application:

Clad Thickness Ratio: Make sure the stainless steel layer is thick enough to provide corrosion protection, but not too thick to unnecessarily increase costs. Standard thickness ratios range from 10/90 to 20/80 (stainless steel/substrate). The thickness of the cladding layer should be at least half the thickness of the parent material.

Welding and Forming: Clad plates require specific welding methods to avoid delamination. Check with your supplier for welding compatibility and edge cladding requirements.

Service Conditions: Know your environment – is it acidic, alkaline, or hot? Select the appropriate stainless steel grade (e.g., 316L, 2205, Incoloy) accordingly.

Bond Strength and Integrity: Make sure the manufacturer provides shear strength, peel testing, and ultrasonic testing.

Compliance with International Standards: Be sure to check for compliance with ASTM, ASME, EN, or GB standards depending on the project location.

Have questions about clad layer thickness, grade, or welding compatibility? Please contact Huaxiao Metal, our technical engineers will provide you with a free consultation.

Advantages of Clad Stainless Steel

| Feature | Clad Stainless Steel | Solid Stainless Steel |

|---|---|---|

| Corrosion Resistance | Excellent (via stainless steel layer) | Excellent |

| Strength & Load Capacity | High (due to carbon steel base) | Moderate |

| Cost | More economical | Expensive |

| Weldability | Easier due to composite structure | Can be complex |

| Customizability | High (layer combinations possible) | Limited |

Composite stainless steel is the future of industrial design – combining corrosion resistance and mechanical strength at a very competitive price. Whether you are an engineer, project purchaser or distributor, understanding how composite metals work will help you make more informed material decisions.

Looking for high-quality composite stainless steel?

Contact Huaxiao Metal today.

Where Is Clad Stainless Steel Used?

Clad stainless steel is used in a wide range of industries, including:

Chemical and Petrochemical Processing – Reactors, columns, and tanks

Water Treatment & Desalination Plants – Corrosion-resistant piping and walls

Power and Nuclear Industries – Pressure vessels and steam lines

Oil & Gas Industry – Clad pipes, separators, and pressure heads

Flue Gas Desulfurization Systems – High acid resistance needed

These applications benefit from the chemical resistance of stainless steel without the high material cost of using stainless alone.

Not sure if clad stainless steel is right for your application? Send us your project specifications and we’ll get back to you with a competitive price within 24 hours.

Common Material Combinations

| Cladding Material | Base Material | Typical Use Cases |

|---|---|---|

| 304 / 316L | Q235B / SA516Gr70 | Tanks, vessels, heat exchangers |

| 2205 Duplex | Alloy Steel | Offshore, marine, pressure equipment |

| Inconel / Monel | Carbon Steel | Chemical, high-temperature environments |

Clad stainless steel plates, composite sheets, and clad coils, tubes can all be customized based on application needs.

How to Choose a Clad Stainless Steel Supplier?

When sourcing clad stainless steel, look for manufacturers who offer:

Customizable clad layer materials and thicknesses

Experience with both hot roll and explosive bonding

Global quality certifications (ISO, ASTM, ASME, EN, GB)

In-house testing: ultrasonic, shear strength, corrosion resistance

OEM/ODM capability and competitive export logistics

Huaxiao Metal is a trustworthy stainless steel composite manufacturer and supplier that supports customization of product size and shape, and has a large number of products in stock and can be delivered at any time. Contact us immediately to obtain our inventory information and stainless steel prices, etc.