As a versatile alloy that combines high strength, excellent machinability and outstanding corrosion resistance, 6061-T6 aluminum bar is one of the preferred materials for engineers and designers around the world. Whether your project involves precision CNC machining, structural frames or transportation components, understanding its core properties is the key to success.

Huaxiao Metal is not only your supplier but also your technical partner. We supply 6061-T6 aluminum bars that meet international standards and offer professional material selection advice for your specific application.

Basic Introduction to 6061-T6 Aluminum Bar:

The name of 6061-T6 aluminum bar contains two core elements: alloy composition and heat treatment state.

“6061” alloy: This is a precipitation-hardened aluminum alloy with magnesium and silicon as the main alloying elements. This combination gives it excellent mechanical properties and a wide range of application potential.

“T6” heat treatment temper: This is the most common state of 6061 aluminum. It has been solution heat-treated and artificially aged. In simple terms, this process heats the aluminum to a specific temperature, cools it quickly, and then keeps it at a lower temperature for a long time, so that its internal structure reaches the best strength and hardness.

Features and Performance:

- High Strength: The 6061-T6 aluminum bar has excellent tensile strength, making it ideal for numerous engineering applications.

- Corrosion resistance: The natural oxide layer of aluminum gives 6061-T6 alloy good corrosion resistance and is suitable for a variety of environments.

- Lightweight: Compared to other metals, aluminum’s lightweight properties provide more design flexibility for various industries.

6061-T6 Technical Specifications:

The following are typical mechanical properties of 6061-T6 aluminum bars. Please note that the specific values may vary slightly due to different standards (ASTM, EN, etc.) and specific batches.

| Property | Typical Value (Metric) | Typical Value (Imperial) |

|---|---|---|

| Tensile Strength | ≥ 290 MPa | ≥ 42,000 psi |

| Yield Strength | ≥ 241 MPa | ≥ 35,000 psi |

| Brinell Hardness | 95 HB | 95 HB |

| Elongation | 12–17% | 12–17% |

| Density | 2.7 g/cm³ | 0.0975 lb/in³ |

| Melting Point Range | 582–652 °C | 1080–1205 °F |

Disclaimer: The above values are typical reference data. For final design purposes, please request the Material Test Certificate (MTC) for your specific batch.

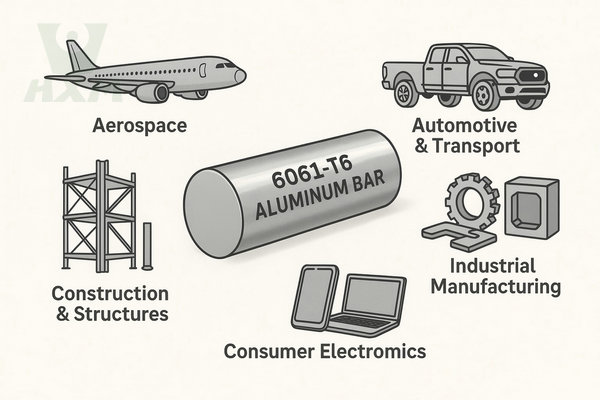

Application Areas:

6061-T6 aluminum body is widely used in aerospace, automobile manufacturing, construction engineering, sports equipment, and other fields. Its superior strength and lightweight properties make it one of the materials of choice for designers and engineers.

| Industry | Specific Applications | Reasons for Selection |

|---|---|---|

| Aerospace | Aircraft structural parts, wings, fuselage fittings, and landing gear components | High strength, lightweight, fatigue resistance |

| Automotive & Transport | Truck body frames, suspension components, wheels, and marine fittings | Lightweight, corrosion-resistant, strong |

| Industrial Manufacturing | Precision machined parts, molds, automation equipment structures | Excellent machinability, dimensional stability |

| Construction & Structures | Building formwork, piping, platforms, and walkways | Corrosion resistance, medium strength, easy to join |

| Consumer Electronics | Premium phone cases, laptop housings, and electronic heat sinks | Good texture, excellent heat dissipation, easy to form |

Manufacturing Process:

The manufacturing process of 6061-T6 aluminum bars is a complex and precise process, which involves heat treatment steps and mechanical processing. The following is a detailed expansion of the alloy manufacturing process:

4.1 Heat Treatment Steps:

6061-T6 aluminum alloy undergoes heat treatment during the manufacturing process. This is to increase its strength and hardness. The heat treatment step involves heating the aluminum rod to high temperatures, typically in the range of 500°C to 600°C, and then controlling the cooling rate to achieve a solid solution and recrystallization of the alloy. The key to this step is to rearrange the crystal structure of the aluminum alloy through appropriate temperature and time control, thereby enhancing its mechanical properties.

4.2 Mechanical Processing Process:

After heat treatment, the 6061-T6 aluminum bar enters the machining stage to achieve the final specifications and shape. This stage involves multiple steps:

- Forging: Aluminum rods may undergo a forging process, which improves its crystal structure by applying pressure and changes in shape, further increasing its strength.

- Extrusion: 6061-T6 aluminum alloy is also often put through an extrusion process, where the blank is squeezed into the desired shape through a specific die, which helps improve its density and mechanical properties.

- Stretching: Aluminum bars may undergo a stretching process that gives them greater strength in specific directions. This processing method helps to adjust the crystal structure of the aluminum alloy and increases its fatigue resistance.

4.3 Surface Treatment:

After manufacturing, 6061-T6 aluminum bars may require surface treatment to meet the requirements of different applications. This may include anodizing to create a corrosion-resistant oxide layer or coating to increase surface hardness and aesthetics.

4.4 Quality Control:

Quality control is an integral part of the entire manufacturing process. By using advanced testing equipment and technology, manufacturers can ensure that each aluminum rod meets strict specifications and standards. This includes precise measurement and monitoring of size, shape, chemical composition, and mechanical properties.

By having an in-depth understanding of the manufacturing process of the 6061-T6 aluminum bar, users can better understand its high-performance characteristics and provide a basis for its successful use in different applications. This meticulous manufacturing process provides a solid foundation to ensure the reliability and stability of 6061-T6 aluminum bars.

Comparison of 6061-T6 with Other Aluminum Alloys:

As a widely used aluminum alloy, 6061-T6 aluminum alloy has unique characteristics compared with other aluminum alloys. Below is a comparison with some common aluminum alloys, highlighting the advantages and applicability of 6061-T6 aluminum alloy:

5.1 Comparison with 6063 Aluminum Alloy:

Strength: 6061-T6 alloy generally has higher strength than 6063 alloys, making it more suitable for applications requiring higher tensile strength.

Processability: 6063 alloy is easier to form when heat treated, while 6061-T6 alloy gains higher hardness through heat treatment and therefore may be more desirable where higher strength is required.

Corrosion resistance: Because 6061-T6 alloy contains copper and other elements, it has better corrosion resistance than 6063 alloys.

5.2 Comparison with 7075 Aluminum Alloy:

Strength: 7075 aluminum alloy is a high-strength aluminum alloy, but it is also denser and heavier. In terms of lightweight design, 6061-T6 alloy may be more suitable.

Fatigue resistance: 7075 alloy has better fatigue resistance under high strength conditions and is suitable for some applications that require extremely high strength and durability.

Cost: Relative to 7075 alloy, 6061-T6 alloy is generally more affordable, providing a balance of performance and cost.

5.3 Comparison with 2024 Aluminum Alloy:

Corrosion resistance: 6061-T6 alloy has better corrosion resistance than 2024 alloy, which makes it more suitable in environments that require higher corrosion resistance.

Processability: 2024 alloy is generally difficult to process after heat treatment, while 6061-T6 alloy maintains relatively good processability after heat treatment.

Application fields: 2024 alloy is often used in the aviation field, while 6061-T6 alloy is widely used in aviation, automobiles, construction, and other fields.

By comparing it with other aluminum alloys, we can have a clearer understanding of the advantages and applicability of 6061-T6 aluminum alloy. This comprehensive comparison helps develop optimal materials selection strategies to ensure optimal performance and economics in a specific application.

Why Choose 6061-T6 Aluminum Bar?

6061-T6 aluminum bar is popular because it strikes an ideal balance of key properties.

Excellent Machinability

The hardness in the T6 state is ideal for CNC machining, such as cutting, drilling, milling, etc., which can form a smooth surface finish while reducing tool wear.

High Strength-to-Weight Ratio

It provides considerable strength, but the density is much lower than steel, making it an ideal choice for aerospace, automotive lightweighting, and any structural application that requires weight reduction.

Superior Corrosion Resistance

The surface of 6061 aluminum can naturally form a dense oxide film, which effectively resists corrosion from the atmosphere and most media. After anodizing, its corrosion resistance and aesthetics can be further improved.

Good Weldability & Formability

It can be welded using a variety of methods and has good cold formability in the annealed state, which facilitates the design and manufacture of complex structures.

Why choose Huaxiao Metal as your 6061-T6 Aluminum Bar supplier?

At Huaxiao, we understand that you need more than just materials, but also a reliable supply chain partner.

Quality Assurance and Certification: All 6061-T6 aluminum bars we provide are traceable, and we can provide complete material test certificates (MTC) and third-party inspection reports upon your request.

Customized services: Whether you need a specific length, diameter, or precision cutting or surface treatment, we can meet your customized needs.

Global Logistics and Professional Packaging: We have extensive international transportation experience to ensure that your goods are delivered safely and on time to any port in the world.

Expert team support: Our team of experienced metal material experts is always ready to answer your technical questions and help you optimize your material selection.

In Conclusion:

6061-T6 aluminum bar is a versatile material whose excellent properties make it widely used in many industries. Through this article, readers will gain a deeper understanding of the superior properties of this aluminum alloy and how it functions in a variety of applications.