Are you sourcing a stainless steel that delivers an exceptional balance of hardness, corrosion resistance, and cost-effectiveness? Your search may end with 5Cr13 stainless steel, a versatile material trusted across numerous industries.

As a leading global supplier of metal solutions, Huaxiao Metal provides this in-depth guide to help you understand the full capabilities of 5Cr13 steel, ensuring you make the most informed purchasing decision for your project.

Need to source 5Cr13 or equivalent steel grades? Contact our material experts today for a no-obligation quote and technical consultation!

What is the Material of 5Cr13?

5Cr13 is a stainless steel with a carbon mass fraction of 0.4-0.5%.

Cr12.5-14% stainless steel.

Characteristics:

The thermal conductivity of this material is low, and the Cr content is higher than that of general alloy materials. During strong grinding, when the temperature reaches a certain limit, the Cr element will have an affinity with the abrasive in the grinding wheel and stick the abrasive together.

The aperture of the grinding wheel will soon be blocked by metal particles, and the grinding performance will decrease, resulting in extrusion grinding and slipping. In this way, the temperature will quickly rise, causing the workpiece to burn during annealing. After quenching, the steel has a very high hardness (60HRC), excellent wear resistance, low permeability, good toughness, and excellent corrosion resistance at a temperature of 700~C.

Is the Alloy Steel the Same Material as 5Cr Steel?

Alloy steel and 5Cr steel are not the same material.

5Cr is a kind of alloy steel, and alloy steel is a general term.

Alloy steel refers to steel in addition to iron, carbon, adding other alloying elements, it is called alloy steel.

Equivalent Grades of 5 Cr 13 Stainless Steel

To help you navigate international specifications, 5 Cr13 is comparable to several grades from other global standards. While chemical compositions may not be identical, these equivalents have very similar performance characteristics and are often considered functional alternatives.

For standard 5 Cr13:

| Standard | Equivalent Grade |

| Chinese (GB) | 5Cr13 / 50Cr13 |

| American (AISI) | 420HC |

| German (DIN) | X46Cr13 (W.Nr. 1.4034) |

| Japanese (JIS) | SUS420J2 |

The enhanced 5Cr13MoV variant, which includes Molybdenum and Vanadium, is most famously compared to the high-performance German steel used in many premium knives:

| Standard | Equivalent Grade |

| Chinese (GB) | 5Cr13MoV |

| German (DIN) | X50CrMoV15 (W.Nr. 1.4116) |

Note: For critical applications, always consult with a material specialist at Huaxiao Metal to verify the precise grade that meets your technical requirements.

What Kind of Steel is 5Cr13?

Martensitic stainless steel has good hardenability it has high hardness, toughness, good corrosion resistance, heat strength, and cold deformation properties, shock absorption is also very good. High or low-temperature tempering is required, but tempering treatment between 370-560°C should be avoided.

Stainless steel whose mechanical properties can be adjusted by heat treatment is, in common parlance, a class of hardenable stainless steel. Typical grades are Cr13 type, such as 2Cr13, 3Cr13, 4Cr13, 5Cr13 and so on. Higher hardness after quenching, different tempering temperatures with different toughness combinations, mainly used for steam turbine blades, tableware, and surgical instruments.

Extended Information

200 series – chromium-nickel-manganese austenitic stainless steels (whether it can be used for food is controversial)

300 Series-Chromium-Nickel Austenitic Stainless Steels

Type 301 – Good ductility, used for molded products. Can also be hardened rapidly by machining. Weldability is good. Wear resistance and fatigue strength superior to 304 stainless steel.

Type 302-Corrosion resistance is the same as 304, with better strength due to the relatively high carbon content.

Type 303 – By adding a small amount of sulfur and phosphorus to make it easier to cut and process than 304.

Type 304 – general type; that is, 18/8 stainless steel. GB grade 0Cr18Ni9.

Type 309 – has better temperature resistance than 304.

What is the Difference Between 3Cr13, 4Cr14, 5Cr15?

To help you choose the right grade for your needs, here is a comparison between 5Cr13 and its sister steels, 3Cr13 and 4Cr13.

| Feature | 3Cr13 (30Cr13) | 4Cr13 (40Cr13) | 5Cr13 (50Cr13) |

| Avg. Carbon Content | ~0.3% | ~0.4% | ~0.5% |

| Hardness (Post-HT) | Lower (HRC ~52-55) | Medium | Higher (HRC ~55-58) |

| Wear Resistance | Good | Better | Best |

| Toughness | Best | Better | Good |

| Primary Use Case | Applications requiring high toughness & moderate hardness | General-purpose tools need better wear resistance | Demanding applications requiring high hardness & edge retention |

Difference in Elemental Content

3Cr13 average carbon content are 0,3%, 13% chromium content

4Cr14 average carbon content is 0,4%, chromium content 14%.

5Cr15 average carbon content are 0,5%, chromium content of 15%.

Mechanial Properties of the Difference

Strength level and other mechanical properties from low to high

3Cr134Cr145Cr15

In Summary:

3Cr13 is the softest and toughest, ideal for applications where flexibility is critical.

5Cr13 is the hardest and most wear-resistant, offering the best edge-holding capability.

4Cr13 provides a balanced profile between the two.

Unsure which Cr13 grade is right for your product? Click contact us now, and our material specialists will provide a complimentary consultation.

3Cr13, 4Cr14 Mechanical Properties

3Cr13

Tensile strength b (MPa): quenched and tempered, ≥735

Conditional yield strength 0.2 (MPa): quenched and tempered, ≥ 540

Elongation 5 (%): quenched and tempered, ≥12

Section shrinkage (%): quenched and tempered, ≥40

Impact work Akv (J): quenched and tempered, ≥24

Hardness: annealed, ≤235HB; quenched and tempered 48~53HRC

4Cr14

Tensile strength b (MPa): ≥705

Conditional yield strength 0.2 (MPa): ≥315

Elongation 5 (%): ≥20

Section shrinkage (%): ≥35

Hardness:≤248HB

What is 5Cr13Mov Steel?

5Cr13MoV stainless steel strip is mainly used for making high-grade cutting tools, medical equipment, etc.

a. Because of the high carbon content, the hardness after quenching can reach HRC58.

b. The high Cr in the product can improve the hardenability and wear resistance of the steel, and can improve the corrosion resistance of the steel and the antioxidant effect.

c. Molybdenum content of more than 0.5% in the product can obviously improve the hardenability and thermal strength of the steel, prevent tempering brittleness, improve toughness, wear resistance and corrosion resistance.

d. Vanadium in the product can refine the grain organization of steel, improve the strength, toughness, and wear resistance of steel.

Understanding the 5Cr13MoV Variant

You will frequently encounter the 5Cr13MoV designation. This is an enhanced version of the standard 5Cr13, with two crucial alloying elements added:

Molybdenum (Mo): Improves the steel’s strength at high temperatures, toughness, and overall corrosion resistance, especially against pitting corrosion (e.g., from chlorides).

Vanadium (V): Helps produce a finer grain structure in the steel, which significantly increases its strength, wear resistance, and toughness.

As a result, 5Cr13MoV offers superior overall performance compared to standard 5Cr13 and is often the preferred choice for higher-end knives and more demanding industrial components.

Common Applications of 5Cr13 & 5Cr13MoV

Thanks to its balanced performance and excellent value, 5 Cr13 stainless steel is widely used in a variety of demanding applications:

Cutlery & Knives: This is the most popular application. It’s a go-to material for everyday kitchen knives, multi-tools, outdoor survival knives, and pocket knives.

Medical Instruments: Its good corrosion resistance and ability to be sterilized make it suitable for surgical blades, dental instruments, and other hygienic tools.

Hand Tools: Used to manufacture durable scissors, shears, and other cutting implements.

Mechanical Parts: Ideal for producing components that require wear resistance in mildly corrosive environments, such as shafts, valves, and fasteners.

FAQ

Does 5Cr13 steel rust?

5Cr13 is a stainless steel, which means it “stains less,” not that it will never rust. Under normal conditions and with proper care, it has excellent rust prevention capabilities. However, prolonged exposure to harsh, salty, or acidic environments without cleaning can eventually lead to rust spots.

Is 5Cr13 Stainless Steel Magnetic?

Yes, 5Cr13 is a magnetic stainless steel due to its martensitic structure. After heat treatment, it becomes harder and retains magnetic properties, making it suitable for applications requiring magnetic response.

Is 5Cr13 a good steel for high-end kitchen knives?

5Cr13 is an excellent material for high-performance, cost-effective kitchen knives for both home and commercial use. For elite, professional-grade chef’s knives where ultimate edge retention is the top priority, more exotic “super steels” may be used, but 5Cr13 remains one of the best value propositions on the market.

What forms of 5Cr13 steel does Huaxiao Metal supply?

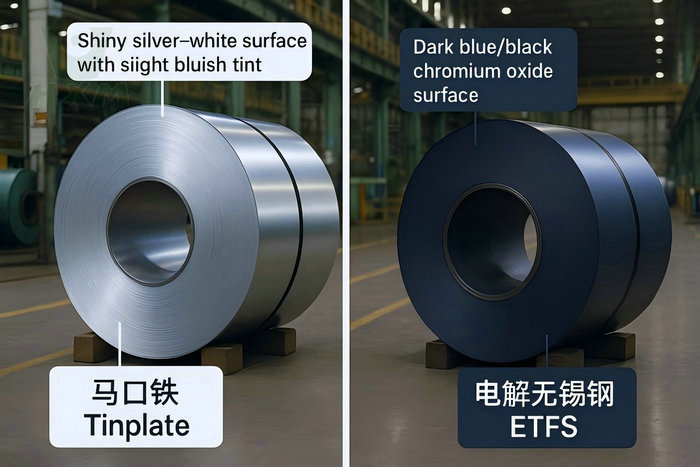

At Huaxiao Metal, we supply 5Cr13 and 5Cr13MoV in a variety of forms to meet your manufacturing needs, including:

Steel Plate / Sheet

Steel Coil

Steel Strip

Steel Bar

We also offer custom processing services such as cutting, slitting, and surface finishing.

Choose Huaxiao Metal as Your Reliable 5Cr13 Steel Supplier

At Huaxiao Metal, we do more than just supply raw materials. We provide complete, end-to-end solutions for our clients. Whether your project is large or small, our team is committed to delivering the highest quality 5Cr13 steel that meets your precise technical specifications and budget.

Wide Inventory: We stock various thicknesses and dimensions of 5Cr13 plates, coils, and bars.

Quality Assurance: Mill test certificates and full traceability.

Global Exporter: Fast shipping to over 60 countries.

Custom Processing: Cutting, slitting, polishing, and more.

5Cr13 stainless steel is a versatile martensitic steel ideal for applications requiring wear resistance and moderate corrosion protection. Whether you’re sourcing knife materials, mechanical components, or industrial tools, Huaxiao Metal is your trusted 5Cr13 stainless steel supplier in China.

📩 Looking for 5Cr13 stainless steel prices or suppliers? Contact us now to get a quote today!