In the field of engineering, material selection is crucial because different materials have different properties and are applicable scenarios. Among steels, SPCC vs Q235 are two common standards. They have obvious differences in chemical composition, use, and processing performance. The wrong choice can lead to costly production delays, poor surface quality, and even structural failure.

Therefore, it is crucial to understand the fundamental differences between common steel grades such as SPCC and Q235. The former provides a perfect surface for high-end products, while the latter provides solid strength for your reliable structures.

This guide is written for engineers and procurement managers who need to make the right choice. We will not only show you what they are, but also show you how to use their unique advantages to gain business advantages.

SPCC vs Q235: What’s the Difference?

For those who need a fast answer, here is a high-level comparison of the two materials:

| Feature | SPCC Steel | Q235 Steel |

| Standard | JIS G 3141 (Japanese) | GB/T 700 (Chinese) |

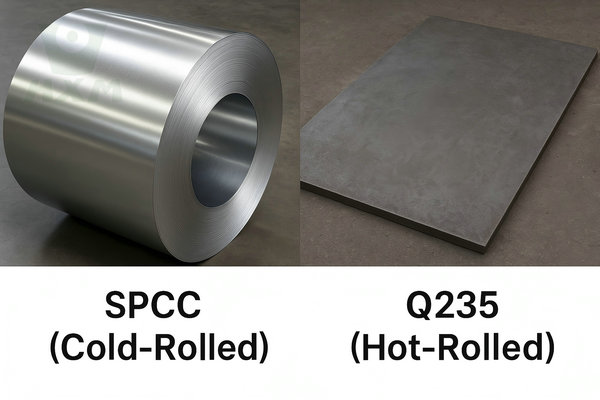

| Manufacturing | Cold-Rolled | Hot-Rolled |

| Main Characteristic | Excellent Formability & Surface | Good Strength & Weldability |

| Primary Use | Automotive parts, appliances, enclosures | Structural beams, bridges, and construction |

| Surface Finish | Smooth, oily, and clean | Rough, with mill scale |

| Relative Cost | Higher | More Economical |

SPCC and Q235 are two common carbon structural steel materials. They differ in chemical composition, mechanical properties, application fields, and usage environment. A detailed comparison and analysis of these two materials will be made below.

What is SPCC Steel? (JIS G 3141)?

SPCC is a commercial quality cold-rolled steel grade defined by the Japanese Industrial Standard (JIS) G 3141. The name stands for “Steel Plate Cold Commercial.” The “cold-rolled” process refers to the further processing of the material at room temperature after it has been hot-rolled. This results in a steel with a smoother, more uniform surface, tighter dimensional tolerances, and improved formability.

Key characteristics of SPCC include:

Excellent for bending and deep drawing.

A clean and high-quality surface finish, ideal for painting and coating.

Lower carbon content makes it softer and more ductile.

What is Q235 Steel? (GB/T 700)?

Q235 is a plain carbon structural steel grade specified by the Chinese National Standard (GB/T 700). The “Q” stands for “Yield Strength”, and “235” indicates that its minimum yield strength is 235 MPa. It is a hot-rolled steel, meaning it’s processed at high temperatures. Q235 is one of the most widely used steels in China for general construction and structural applications.

Key characteristics of Q235 include:

Good overall mechanical properties, particularly in terms of strength and toughness.

Excellent weldability.

Highly cost-effective and readily available.

Chemical Composition of SPCC vs Q235:

| Element | SPCC (%) | Q235 (%) |

|---|---|---|

| C | < 0.15 | < 0.22 |

| Mn | < 0.60 | < 1.60 |

| Si | < 0.05 | < 0.35 |

| P | < 0.050 | < 0.050 |

| S | < 0.050 | < 0.045 |

Mechanical Properties of SPCC vs Q235:

Here’s the comparison table for the mechanical properties of SPCC and Q235:

| Property | SPCC | Q235 |

|---|---|---|

| Strength (MPa) | 270-410 | 375-500 |

| Yield Strength (MPa) | ≥ 130 | 235 |

| Elongation (%) | ≥ 28 | ≥ 26 |

| Impact Energy (J) | – | ≥ 27 |

This table highlights the differences between SPCC and Q235 in strength, yield strength, elongation, and impact energy. These mechanical properties are crucial for engineering design and material selection.

Cost SPCC vs Q235:

The cost of (Steel Plate Cold Rolled Coiled) SPCC and Q235 steel can vary depending on factors such as market demand, production volume, and supplier pricing. Generally, Q235 steel tends to be more economical compared to SPCC due to its lower manufacturing costs and widespread availability, especially in China, where it’s a commonly used steel grade.

SPCC, on the other hand, might be slightly more expensive due to its specific production processes and potentially higher quality standards. However, precise cost differentials can fluctuate over time and may require inquiry with metal suppliers or market analysis to determine accurately.

Characteristics of SPCC vs Q235:

Here’s a comparison of the characteristics of SPCC and Q235 steel grades:

| Characteristic | SPCC | Q235 |

|---|---|---|

| Material Type | Steel | Steel |

| Standard | Japanese standard JIS G 3141 | Chinese standard GB/T 700-2006 |

| Chemical Composition | Low carbon steel with | Carbon structural steel |

| specific limits on | with defined chemical | |

| carbon, manganese, | composition including | |

| phosphorus, sulfur, and | carbon, manganese, | |

| silicon content | phosphorus, sulfur, and | |

| silicon content | ||

| Strength | Moderate | High |

| Ductility | Moderate | High |

| Weldability | Good | Good |

| Corrosion Resistance | Low | Low |

| Usage | Typically used for | Commonly used in |

| applications requiring | general engineering | |

| good surface quality | structures, such as | |

| and flatness, such as | bridges, buildings, | |

| automotive components, | and ships | |

| household appliances, | ||

| etc. |

This table outlines the key characteristics of SPCC and Q235 steel grades, including their chemical composition, strength, ductility, weldability, corrosion resistance, and typical usage. SPCC is often chosen for its good surface quality and flatness, making it suitable for applications like automotive components and household appliances. At the same time, Q235 is commonly used in various general engineering structures due to its higher strength.

Surface Finish & Treatment

The manufacturing process directly impacts the surface.

SPCC’s cold-rolled surface is smooth, clean, and slightly oily. This is a perfect substrate for high-quality painting, powder coating, and electroplating with minimal preparation.

Q235’s hot-rolled surface has a bluish-grey, rough “mill scale” from cooling in the air. This scale must be removed by sandblasting or acid pickling before any coating can be applied.

Key Differences Explained Application & Use Cases

This is the most important distinction.

SPCC is the material of choice when formability and surface quality are paramount. Its ability to be stamped into complex shapes without cracking makes it ideal for:

- Automotive body panels (doors, hoods, fenders)

- Household appliance casings (refrigerators, washing machines)

- Furniture and electrical enclosures

Q235 is used when strength, rigidity, and load-bearing capacity are the priorities. It forms the backbone of countless structures.

- Building frames, I-beams, and structural supports

- Bridges and towers

- Welded tanks and machine bases

Which Steel is Right for Your Project?

Making the right choice is simple when you focus on your primary requirements.

Choose SPCC if your project requires:

Complex bending, stamping, or deep drawing.

A premium, paint-ready surface finish.

Tight dimensional tolerances.

The final part is a non-structural cover, panel, or casing.

Choose Q235 if your project requires:

High strength and structural integrity to bear loads.

Extensive welding during fabrication.

Cost-effectiveness is a major driver.

The surface finish is secondary or will be heavily prepped before coating.

Frequently Asked Questions

Is SPCC a type of stainless steel?

No, SPCC is a carbon steel, not a stainless steel. It lacks the minimum 10.5% chromium content required to form the passive, corrosion-resistant layer that defines stainless steel. Like Q235, SPCC will rust if not protected by a coating or oil.

Can Q235 steel be used for outdoor structures?

Absolutely, but it must be properly protected from the elements. Due to its low corrosion resistance, structural Q235 steel used outdoors must be coated, most commonly through hot-dip galvanizing or a robust industrial painting system, to prevent rust and ensure a long service life.

What is a common international equivalent for Q235 steel?

The closest European equivalent to Q235 is S235JR (under the EN 10025 standard). The “235” in both standards refers to the same minimum yield strength of 235 MPa, making them functionally similar in many structural applications.

Partner with Huaxiao Metal for Your Steel Needs

Navigating the world of steel grades can be complex, but you don’t have to do it alone. At Huaxiao Metal, our team of material experts has decades of experience helping clients select the perfect steel for their specific needs, balancing performance, cost, and processability.

Whether you need high-quality SPCC coils with a superior finish or cost-effective Q235 plates for a major structural project, we can supply materials that meet rigorous international standards.

Let our experts help you find the ideal steel for your next project. Tell us what you need and we’ll provide a competitive quote and clear follow-up options.

In Conclusion:

Although both SPCC and Q235 are common steel standards, they have significant differences in chemical composition, usage and processing properties. Therefore, when selecting materials, which material to use should be determined based on specific engineering requirements and application scenarios. Correct selection of materials can ensure the quality and reliability of engineering projects, thereby improving the success rate and efficiency of the project.

Materials Engineer at Huaxiao Metal with 15+ years of experience in the steel industry.