If you’ve ever worked in construction, manufacturing, or even just used a high-quality kitchen knife, you’ve encountered carbon steel. But a common question we hear is, “Is carbon steel real steel?”

The answer is simple: Yes, carbon steel is a type of real steel. It’s one of the most fundamental and widely used steel alloys in the world. Its defining characteristic is its simplicity and effectiveness, consisting primarily of iron and carbon.

This comprehensive guide will walk you through everything you need to know about carbon steel — from its precise definition and different types to its key properties and how to choose the right kind for your project.

Composition and Characteristics of Carbon Steel

What Exactly is Carbon Steel? (The Definition)

At its core, carbon steel is an iron alloy with a carbon content typically ranging from 0.05% to just over 2.1% by weight. While other elements can be present in trace amounts, it’s the percentage of carbon that is the primary determinant of the steel’s properties.

Here’s the key takeaway:

More Carbon = Harder, stronger steel, but less ductile (more brittle).

Less Carbon = Softer, more ductile steel that is easier to form and weld.

This simple “recipe” is what makes carbon steel so versatile and cost-effective compared to more complex alloys like stainless steel.

Basic Composition

Carbon steel is primarily composed of iron and carbon. Typically, its carbon content is between 0.2% and 2.1%, but it may also contain small amounts of other elements such as silicon, manganese, phosphorus, and sulfur. This simple and basic composition makes carbon steel an ideal structural material.

Strength and Hardness

Carbon steel exhibits varying strengths and hardness due to differences in its carbon content. This enables carbon steel to adapt to applications with various strength requirements in the manufacturing field, making it one of the preferred materials for construction and manufacturing.

Effect of Heat Treatment

The heat treatment process of carbon steel has a profound impact on its properties. By controlling the temperature and cooling rate, the structure of carbon steel can be adjusted, thereby changing its hardness and toughness. This flexibility allows carbon steel to meet the diverse demands for material properties in different industrial sectors.

Application of Carbon Steel in Different Fields

Construction Industry

Carbon steel plays a key role in building structures. Its high strength and corrosion resistance make it ideal for structural elements such as beams, columns, and bridges. Carbon steel’s malleability also helps realize a variety of architectural designs.

Manufacturing

In the manufacturing industry, carbon steel is widely used to make automobiles, machinery, equipment, and tools. Its wear resistance and strength make it ideal for manufacturing highly loaded parts. Manufacturers often rely on reliable carbon steel suppliers to ensure the stability of their production lines.

Energy Industry

In the energy industry, carbon steel is used to make pipes, storage tanks, and other equipment. Its corrosion resistance and high-temperature resistance make it an indispensable material in the oil and gas industry.

The Main Types of Carbon Steel We Supply

At Huaxiao Metal, we classify carbon steel into three main categories based on carbon content. Understanding these types is the first step to selecting the right material.

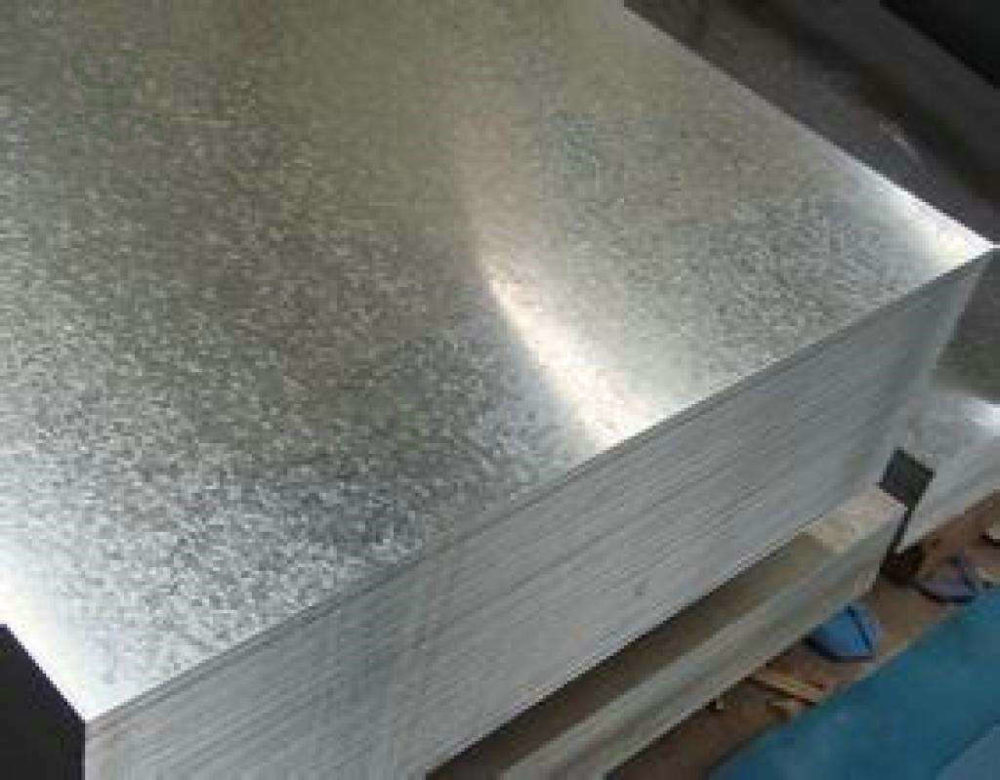

Low Carbon Steel (Mild Steel)

With a carbon content of less than 0.25%, low-carbon steel (also known as mild steel) is the most common type. It is highly ductile, easily weldable, and relatively inexpensive, making it a popular choice for a vast range of applications.

- Key Properties: Excellent formability, weldability, and toughness.

- Common Uses: Automotive body panels, pipes, structural beams, food cans.

Medium Carbon Steel

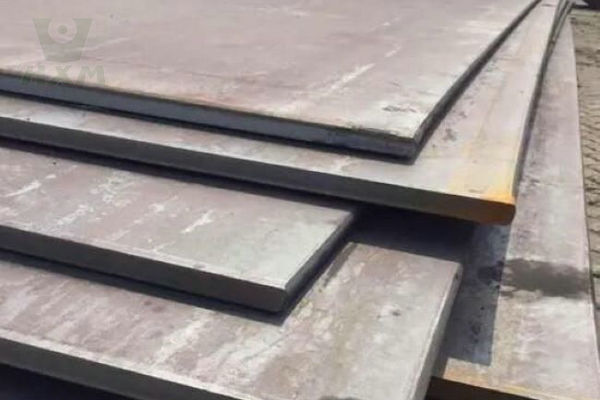

Medium carbon steel contains between 0.25% and 0.60% carbon. The increased carbon content makes it stronger and more wear-resistant than mild steel, but it’s also less ductile. It often requires heat treatment to achieve its full potential.

- Key Properties: Balanced strength and ductility, good wear resistance.

- Common Uses: Gears, axles, shafts, railway tracks, machinery parts.

Looking for the right grade for your machinery? Contact us for medium carbon steel products

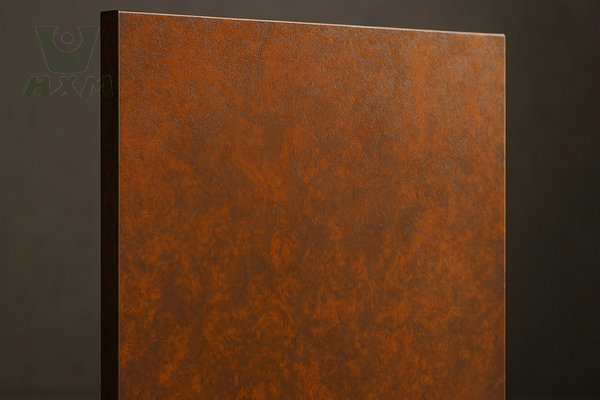

High Carbon Steel (Carbon Tool Steel)

Containing more than 0.60% carbon, this is the hardest and toughest type of carbon steel. Its exceptional hardness and resistance to abrasion make it ideal for applications where a sharp edge and durability are critical.

- Key Properties: Very hard, high strength, excellent wear resistance.

- Common Uses: Cutting tools (drills, knives), high-strength springs, strong wires.

Carbon Steel vs. Stainless Steel: Which is Right for You?

This is one of the most common questions we get. The choice depends entirely on your application’s specific needs. Here’s a quick comparison table:

| Feature | Carbon Steel | Stainless Steel |

| Corrosion Resistance | Low (requires coating or protection) | High (due to chromium content) |

| Cost | Lower | Higher |

| Strength & Hardness | Can be harder and stronger than stainless steel | Generally more ductile and formable |

| Appearance | Matte, rough finish | Bright, polished finish |

| Best For | Strength-focused, cost-sensitive applications | High-moisture environments, aesthetic needs |

Importance of Carbon Steel Suppliers

Reliability and Quality Assurance

Choosing the right carbon steel supplier is crucial to ensuring product quality. Reliable suppliers can provide materials that meet standards, ensuring the performance and reliability of the final product.

Customized Services and Technical Support

Excellent carbon steel suppliers not only provide high-quality materials but also provide customized services and technical support. This is essential to meet the special needs of different industries and projects.

Why Choose Huaxiao Metal for Your Carbon Steel Needs?

Choosing a material is only half the battle; choosing the right supplier is just as critical.

Expert Guidance: Our team has deep knowledge of steel properties and can guide you to the perfect solution.

Quality Assurance: We adhere to strict international quality standards (e.g., ISO, ASTM) to ensure you receive reliable, high-performance steel.

Full-Service Customization: We offer cutting, bending, and finishing services to deliver products that meet your exact project specifications.

Global Shipping: With years of export experience, we can reliably deliver your order anywhere in the world.

In Conclusion

As a real steel material, carbon steel plays an important role in modern society. By understanding the basic composition, properties, and applications of carbon steel in construction, manufacturing, and energy, we can better understand its importance in a variety of industries. At the same time, choosing a reliable carbon steel supplier is critical to ensuring project success and product quality. In the world of carbon steel, suppliers are not only providers of materials, but also partners in the industry’s success.