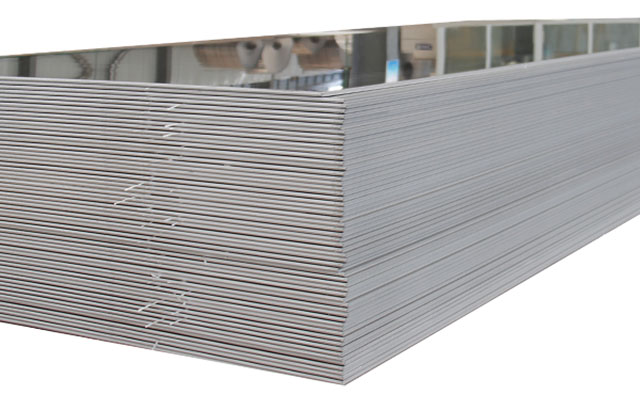

This article aims to explore and provide the numerical measurement of 14 gauge aluminum, shedding light on its dimensions and highlighting its relevance in different contexts.

Gauge System and Aluminum Thickness

- Introduction to the gauge system for measuring sheet metal thickness

- Explanation of the inverse relationship between gauge number and thickness

- Emphasizing the utilization of the American Wire Gauge (AWG) system for aluminum

The Thickness of 14 Gauge Aluminum

Certainly! The thickness of 14 gauge aluminum can be expressed in both inches and millimeters:

- In inches: Approximately 0.0641 inches

- In millimeters: Approximately 1.63 millimeters

These measurements provide an approximate value for the thickness of 14 gauge aluminum.

| Specification | Value | Key Implication |

|---|---|---|

| Thickness (Inches) | 0.0641 inches | A robust thickness suitable for semi-structural use. |

| Thickness (Millimeters) | 1.63 mm | Offers significant dent and puncture resistance. |

| Weight (per square foot) | ~0.91 lbs / sq. ft (~4.42 kg / sq. m) | Substantial weight indicates high density and strength. |

| Need 14g aluminum for a demanding application? Get a Quote from a Material Expert! | ||

How Thick Is 22 Gauge Aluminum?

Determining the specific thickness of materials is crucial in various industries and applications. In the case of 22 gauge aluminum, understanding its precise thickness provides

How Thick Is 16 Gauge Aluminum?

Determining the specific thickness of materials is crucial in various industries and applications. In the case of 16 gauge aluminum, understanding its precise thickness provides

Applications and Significance for 14 Gauge Aluminum

14 gauge aluminum has several applications and significance due to its specified thickness. Here are a few examples:

Industrial Equipment:

Many industrial sectors utilize 14 gauge aluminum for equipment fabrication. It can be employed in the construction of tanks, pipes, ducts, and enclosures due to its durability and resistance to corrosion and heat.

Signage and Displays:

Aluminum is commonly used for signage due to its versatility and ease of fabrication. 14 gauge aluminum sheets can be cut, shaped, and painted to create durable and visually appealing signs and displays for both indoor and outdoor use.

Electrical Enclosures:

Aluminum’s conductivity and non-magnetic properties make it suitable for electrical enclosures and cabinets. 14 gauge aluminum can be used to construct enclosures for electrical control panels, switchgear, and other electrical equipment.

The significance of 14 gauge aluminum lies in its balance between thickness and flexibility. It provides sufficient strength and rigidity while still being manageable and lightweight. Additionally, aluminum’s resistance to corrosion makes it suitable for outdoor and harsh environments, adding to its overall significance in various industries and applications.

Construction and Architecture:

Sheet Metal Fabrication:

The significance of 14 gauge aluminum lies in its balance between thickness and flexibility. It provides sufficient strength and rigidity while still being manageable and lightweight. Additionally, aluminum’s resistance to corrosion makes it suitable for outdoor and harsh environments, adding to its overall significance in various industries and applications.

Engineering and Manufacturing Considerations

When working with 14 ga aluminum in engineering and manufacturing, there are several considerations to keep in mind:

Strength and Load-Bearing Capacity: While 14-gauge aluminum offers a balance of strength and weight, it may have a lower load-bearing capacity compared to thicker gauges or other materials. It’s important to assess the specific application and ensure that the chosen gauge can withstand the expected loads and stresses.

Formability and Machinability: 14 gauge aluminum can be easily formed and fabricated using various techniques such as cutting, bending, and welding. However, it is important to consider the specific properties of the alloy being used and select appropriate methods and tools to work with it effectively.

Corrosion Resistance: Aluminum exhibits excellent corrosion resistance, especially when compared to other metals. However, in certain environments or applications where corrosion is a concern, additional protective measures such as coatings or surface treatments may be necessary to enhance its longevity.

Joining Methods: When joining 14 ga aluminum, suitable welding or fastening techniques should be employed. Common methods include TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and mechanical fastening using screws, rivets, or adhesives. Proper selection of the joining method is crucial to maintain the integrity and strength of the assembly.

Thermal Conductivity: Aluminum has high thermal conductivity, making it suitable for applications where heat dissipation is important. In situations where heat transfer needs to be controlled or minimized, additional insulation or thermal barriers may be required.

Material Compatibility: Consider the compatibility of 14 gauge aluminum with other materials it may come in contact with. This is particularly important in situations where galvanic corrosion can occur when aluminum is in contact with dissimilar metals. Proper insulation or protective coatings can help mitigate this issue.

By taking these engineering and manufacturing considerations into account, designers and manufacturers can effectively utilize 14 gauge aluminum in their projects, ensuring optimal performance and longevity.

Frequently Asked Questions

Key questions engineers and fabricators have about working with this robust material.

What is the best way to weld 14 gauge aluminum?

Both TIG and MIG welding are highly effective for 14 gauge aluminum. The material is thick enough to handle the heat of the welding process well, allowing for strong, clean, and structural welds when performed by a qualified professional. It is an ideal thickness for reliable welded fabrications.

How difficult is it to bend or form 14 gauge aluminum?

It is very difficult to bend by hand. Forming 14 gauge aluminum requires heavy-duty machinery, specifically a powerful sheet metal brake. Its thickness provides excellent resistance to bending, which is precisely why it is chosen for applications requiring rigidity.

Is 14 gauge aluminum strong enough for structural use?

Yes, in many cases. It is widely considered a “semi-structural” material. It is strong enough to be used for boat hulls, support brackets, and self-supporting enclosures. For primary building frames, an engineer would need to calculate the specific load requirements, but for most fabrication projects, its strength is more than sufficient.

In conclusion

To conclude, the thickness of 14 gauge aluminum is approximately 0.0641 inches or 1.63 millimeters. This specific thickness measurement serves as a crucial parameter in various industries and applications. Understanding the thickness of 14 gauge aluminum is essential for sheet metal fabrication, construction, industrial equipment manufacturing, signage production, and electrical enclosure construction. By knowing the precise thickness, engineers and manufacturers can make informed decisions regarding the suitability of 14 gauge aluminum for their specific requirements. Additionally, this knowledge allows for accurate calculations of load-bearing capacity, material compatibility, and other critical engineering considerations. Ultimately, recognizing the thickness of 14 gauge aluminum empowers professionals to utilize this versatile material effectively and ensure the successful execution of their projects.